The injection moulding process is a cornerstone of modern manufacturing. John Smith, an industry expert, once stated, "The efficiency of the injection moulding process revolutionizes production." As technology advances, this method continues to gain recognition for its numerous advantages.

This process allows for the rapid production of complex parts with high precision. Companies see significant cost savings and improved efficiency. However, it is essential to recognize potential drawbacks, such as high initial setup costs. Flexibility in design is a major benefit, but it can lead to challenges in material selection.

Many manufacturers underestimate the importance of mold maintenance. Regular upkeep is vital for sustained quality. The injection moulding process offers a unique balance of speed and accuracy. Yet, companies must remain vigilant about potential flaws and strive for continuous improvement. Embracing this mindset can lead to groundbreaking advancements in production quality.

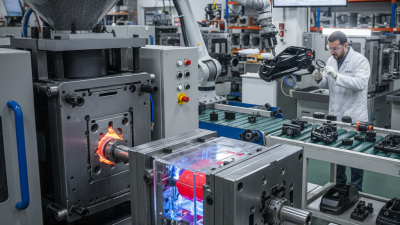

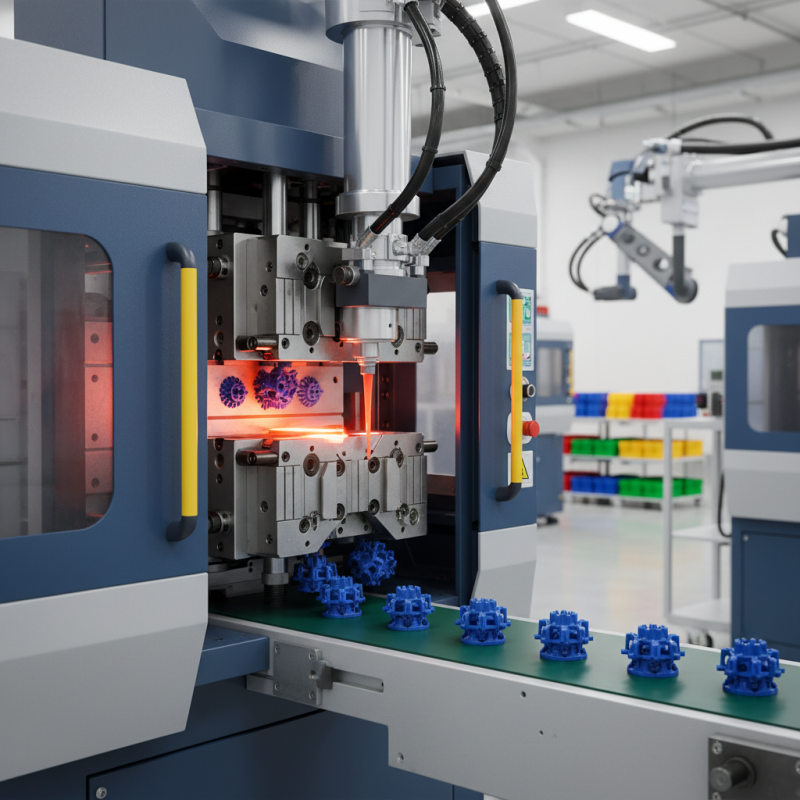

The injection moulding process is a key manufacturing technique widely used across various industries. It involves injecting molten material into a mould, where it cools and solidifies to create a specific shape. This process is highly efficient, producing a large number of identical parts quickly. According to a report from the Plastics Industry Association, the injection moulding sector accounts for over 30% of the global plastics market.

One major advantage of injection moulding is its ability to create complex geometries. This reduces the need for assembly, minimizing production time and costs. However, designing moulds can be expensive and time-consuming. Some estimates suggest that initial mould costs can reach upwards of $100,000, depending on complexity. Additionally, while this method is great for mass production, it may not be ideal for small batches due to high setup costs.

Recycling also poses challenges. Many materials used in the injection moulding process are thermoplastics, which can be recycled. However, the recycling rate for plastic products remains low. According to the Environmental Protection Agency, only about 9% of plastics were recycled in 2021. This raises questions about sustainability in the industry, as more companies seek environmentally friendly alternatives. The injection moulding process offers many benefits, but it also presents issues that need addressing.

The injection moulding process brings significant cost-effectiveness and efficiency to manufacturing. This method allows for large-scale production of items with intricate designs. With the ability to produce thousands of parts quickly, companies can benefit from lower per-unit costs. However, initial setup costs can be high. This might deter small businesses from considering it as an option.

Efficiency in production is another key aspect. The process is highly automated, leading to reduced labor costs. Workers can focus on quality control instead of manual production tasks. Still, automation comes with its own challenges. Sometimes machines malfunction, leading to delays and additional costs. The reliance on technology can create vulnerabilities.

Moreover, the waste generated during injection moulding is relatively low. This is a significant factor in today’s eco-conscious market. However, not all materials used in the process are recyclable. This presents room for improvement. Addressing these issues could enhance sustainability in this manufacturing method.

Injection moulding is a remarkable process known for its versatility. It allows a wide selection of materials. From plastics to metals, the choices are vast. This variety enables designers to choose the best fit for their projects. Each material offers unique benefits and challenges. Understanding these can help make better decisions.

Design options in injection moulding are also impressive. You can create intricate shapes with precision. Complex geometries are easily achievable through this process. However, some designs may pose difficulties during production. It's essential to think about manufacturability. Collaborating with experienced professionals can help navigate this.

Tips: Consider how your design affects material flow. Analyze the wall thickness as it impacts strength and appearance. Also, remember to prototype when possible. This can reveal unanticipated issues. Test your designs with different materials. The right combination can enhance functionality significantly.

The injection moulding process is renowned for its high precision and accuracy in manufacturing parts. It allows for the production of intricate geometries with tight tolerances. According to a report by the Plastics Industry Association, parts produced via injection moulding can achieve tolerances as tight as ±0.005 inches. This level of precision is crucial in industries such as automotive and aerospace, where even minor variations can lead to significant issues.

Using advanced moulding technology, manufacturers can create parts with complex designs. However, achieving this precision requires meticulous planning and high-quality materials. An analysis by Grand View Research indicates that nearly 40% of defects in injection-moulded parts stem from poorly designed moulds or incorrect settings. This highlights the need for constant monitoring and adjustment during production to maintain quality standards.

Additionally, while injection moulding is efficient, it is not without its challenges. For example, cycle times must be carefully controlled to prevent issues like warping or shrinkage. The same report notes that a decrease in cycle time can also increase defects. This balance between speed and quality requires ongoing reflection from manufacturers. Each cycle presents an opportunity to refine the process and improve outcomes.

Injection moulding is a highly efficient manufacturing process known for its sustainability benefits. This method minimizes material waste, often achieving a rate of over 90% in terms of material usage. Unlike traditional machining processes, which can generate significant scrap, injection moulding allows for precision and efficiency, effectively utilizing raw materials. This leads to a notable decrease in energy consumption, with some reports suggesting a reduction of up to 50% compared to alternative methods.

Environmental stewardship is further enhanced by the nature of the materials used. Many injection moulding processes now incorporate recycled plastics and bio-based materials. According to recent industry reports, the use of recycled materials in injection moulding can cut carbon emissions by nearly 30%. This approach not only reduces reliance on virgin materials but also contributes to a circular economy. However, it’s crucial to address that not all recycled materials perform equally. Quality can vary, which raises concerns about the consistency of the final products.

Additionally, the injection moulding industry is exploring innovative ways to improve its sustainability footprint. Companies are investing in eco-friendly production technologies and waste reduction strategies. Yet, challenges remain. The transition phase can be costly and complex. Ensuring that all stakeholders are aligned on sustainability goals often requires a cultural shift. Thus, while the future looks promising, there is still a long pathway to a fully sustainable injection moulding process.