In today's competitive manufacturing landscape, optimizing production processes is crucial for achieving efficiency and quality. One innovative solution that has gained significant attention is the use of a low pressure molding machine. This advanced technology not only streamlines production but also enhances the durability and performance of molded components. By utilizing a low pressure molding machine, manufacturers can reduce cycle times, minimize material waste, and achieve precise control over temperature and pressure settings. The benefits extend beyond operational efficiency; they also include improved product consistency and reduced risk of defects. This article provides a comprehensive overview of strategies and best practices for leveraging low pressure molding machines effectively, ensuring that your production process is maximized for both productivity and cost-effectiveness.

Low pressure molding technologies are increasingly gaining traction in the manufacturing sector due to their unique advantages. A recent survey highlighted that low-pressure injection molding (PIM) can result in manufacturing cycles that are 10-25% faster and reduce melt pressure by 25-50%, which significantly lowers operational costs. This efficiency makes low pressure molding an attractive option for producing intricate parts with irregular shapes, particularly when using iron powders instead of traditional spherical powders.

Moreover, the controlled-viscosity molding technique is making waves in commercial applications, thanks to a patented pulse-packing approach that enhances material flow and reduces waste. This technology not only improves the quality of molded components but also supports sustainability efforts in manufacturing. As industries look towards efficient and eco-friendly processes, the potential of low pressure molding technologies continues to expand, paving the way for innovative applications in lightweight composite structures and additive manufacturing.

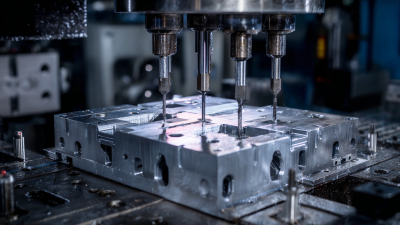

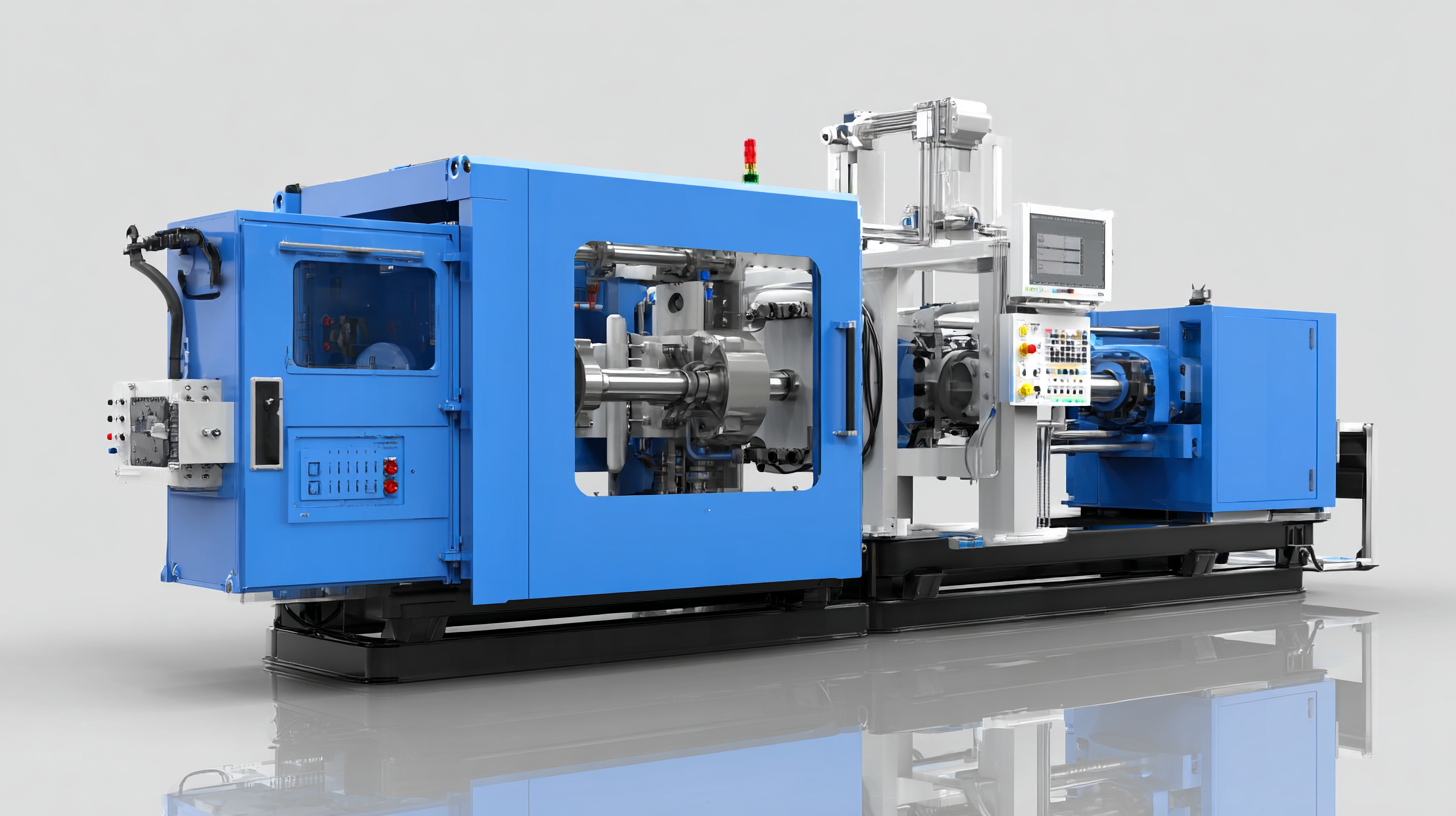

When selecting a low pressure molding machine, several key features can significantly impact your production efficiency. Firstly, consider the machine's temperature control system. A precise temperature regulation allows for consistent molding, which is crucial for achieving high-quality outputs. Machines with advanced thermal management systems ensure that materials are melted evenly, reducing the risk of defects and improving cycle times.

Another important feature to look for is the machine's automation capabilities. Automated processes can enhance productivity by minimizing manual intervention and reducing the likelihood of errors. Machines with user-friendly interfaces and programmable settings allow for quick adjustments and setup changes, streamlining the entire production process.

Tip: Regular maintenance of the molding machine is essential. Schedule periodic checks to ensure that all components are functioning optimally, which can prevent costly downtime and extend the life of the equipment.

Moreover, consider the material compatibility of the machine. It’s essential to ensure that the low pressure molding machine can handle the specific materials you plan to use, whether they are thermoplastics or elastomers. Investing in a versatile machine can save you from the hassle of switching equipment when scaling up production or trying new materials.

Tip: Research machine specifications and user reviews to ensure that the machine’s features align with your production needs and material preferences.

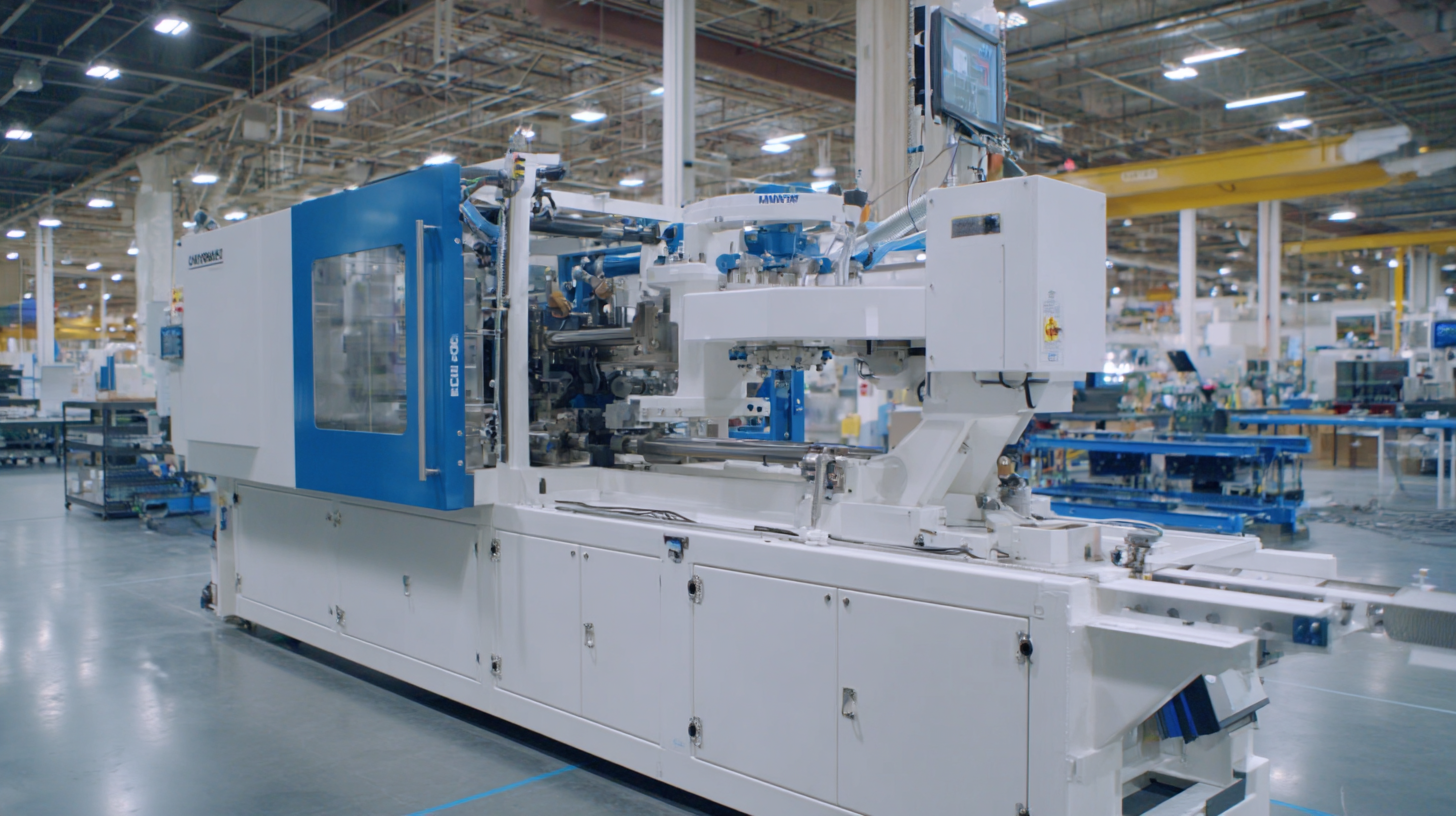

Implementing low pressure molding in your production process can significantly enhance efficiency and product quality. To start, assess your current production workflow and identify areas where low pressure molding could be beneficial. This method is ideal for encapsulating electronic components, protecting them from environmental factors while ensuring a seamless connection between parts. Choosing the right low pressure molding machine is crucial; look for one that meets your production volume and material compatibility needs.

Next, design the mold to fit your specific application requirements. Collaborate with your design team to create molds that facilitate easy loading and unloading of components while minimizing material waste. Once your molds are prepared, conduct a series of test runs to fine-tune the process parameters, including temperature, pressure, and material viscosity. Continuous monitoring and adjustments during these initial runs will help you pinpoint optimal settings that ensure consistent product quality.

Finally, train your staff on the operation and maintenance of the low pressure molding machine. This training will empower them to troubleshoot any issues that may arise and ensure that the production process runs smoothly. By following these steps, you can effectively integrate low pressure molding into your production, leading to improved efficiency and a better end product.

This chart illustrates the production efficiency in terms of units produced per hour before and after the implementation of low pressure molding technology.

To ensure optimal performance of molding machines, regular maintenance is crucial. Start by establishing a routine cleaning schedule to remove any residual material from the machine components. This not only prevents contamination but also helps in identifying wear and tear early on. Pay special attention to the molding surfaces and chambers, as any buildup can lead to defects in the final product.

Additionally, lubrication is key to maintaining the efficiency of low pressure molding machines. Make sure to use the recommended lubricants and check for any leaks that could compromise performance. Regularly inspect hydraulic systems for proper fluid levels and replace filters as necessary. Implementing a checklist for maintenance tasks can help streamline this process and ensure no vital steps are overlooked. By focusing on these maintenance practices, operators can enhance the longevity and reliability of their molding machines, ultimately leading to improved production quality.

| Maintenance Activity | Frequency | Benefits | Notes |

|---|---|---|---|

| Clean the Machine | Weekly | Prevents buildup that can affect performance | Use appropriate cleaning agents |

| Check Fluid Levels | Daily | Ensures optimal operation of hydraulic systems | Top up fluids as necessary |

| Inspect Heating Elements | Monthly | Maintains effective temperature control | Replace any damaged elements |

| Lubricate Moving Parts | Monthly | Reduces wear and tear on machinery | Use recommended lubricants |

| Calibration of Equipment | Bi-Annually | Ensures accuracy and consistency in production | Document calibration results |

| Replace Filters | Quarterly | Improves air quality and efficiency | Use filters that meet specifications |

Low pressure molding technology has revolutionized various industries by enhancing production efficiency and product quality. One notable success story is that of a leading electronics manufacturer that integrated low pressure molding in its production line. By using this method, the company experienced a significant reduction in cycle times while achieving superior encapsulation of delicate components. This resulted in lower defect rates and enhanced durability of their products, allowing them to maintain a competitive edge in a rapidly evolving market.

Another example comes from the automotive sector, where a renowned supplier adopted low pressure molding to create complex components with intricate shapes. This transition led to streamlined workflows and minimized material waste, as the process is typically more efficient than traditional methods. The supplier reported improved production flexibility, enabling them to respond quickly to changing customer demands and project specifications.

Through these case studies, it is evident that companies leveraging low pressure molding technology can optimize their production processes, driving both efficiency and innovation.