In today's competitive manufacturing landscape, optimizing product molding processes is crucial for enhancing production efficiency and reducing costs. As businesses strive to achieve higher output rates and lower waste levels, it becomes imperative to identify effective strategies that can facilitate a notable increase in production efficiency—ideally by as much as 30 percent. This guide delves into various techniques and best practices in product molding that can revolutionize the way manufacturers operate. From adopting advanced technologies to streamlining workflow and improving material usage, each aspect plays a vital role in the optimization process.

By implementing these strategies, manufacturers not only enhance their production capabilities but also position themselves for greater market competitiveness, ensuring higher quality products are delivered in a more timely manner.

To optimize product molding processes and enhance production efficiency by 30 percent, it’s crucial to conduct a thorough analysis of current molding setups. Identifying inefficiencies often involves examining operational workflows, machine performance, and personnel skills. By leveraging technologies like digital twins, manufacturers can create virtual replicas of their production environments, allowing for real-time monitoring and analysis of molding processes. This strategy enables teams to pinpoint bottlenecks and areas that require improvement with greater precision.

Tips:

1. Implement real-time monitoring systems to track machine performance and identify deviations from expected outputs. These insights can guide immediate corrective actions.

2. Regular training programs can address the skilled labor challenge by upgrading the knowledge and capabilities of existing staff, ensuring they can operate advanced machinery effectively.

Additionally, utilizing advanced monitoring techniques such as real-time electrical resistance measurement can enhance the quality of resin transfer molding, ultimately leading to more consistent product quality and reduced waste. In this rapidly evolving manufacturing landscape, embracing digital solutions and continuous training will be vital to achieving significant efficiency gains.

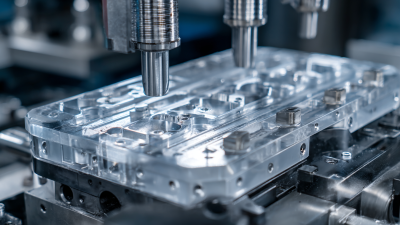

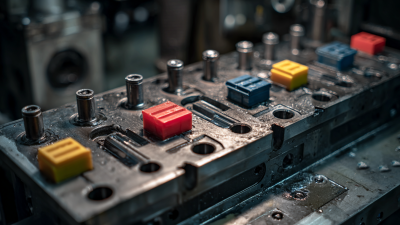

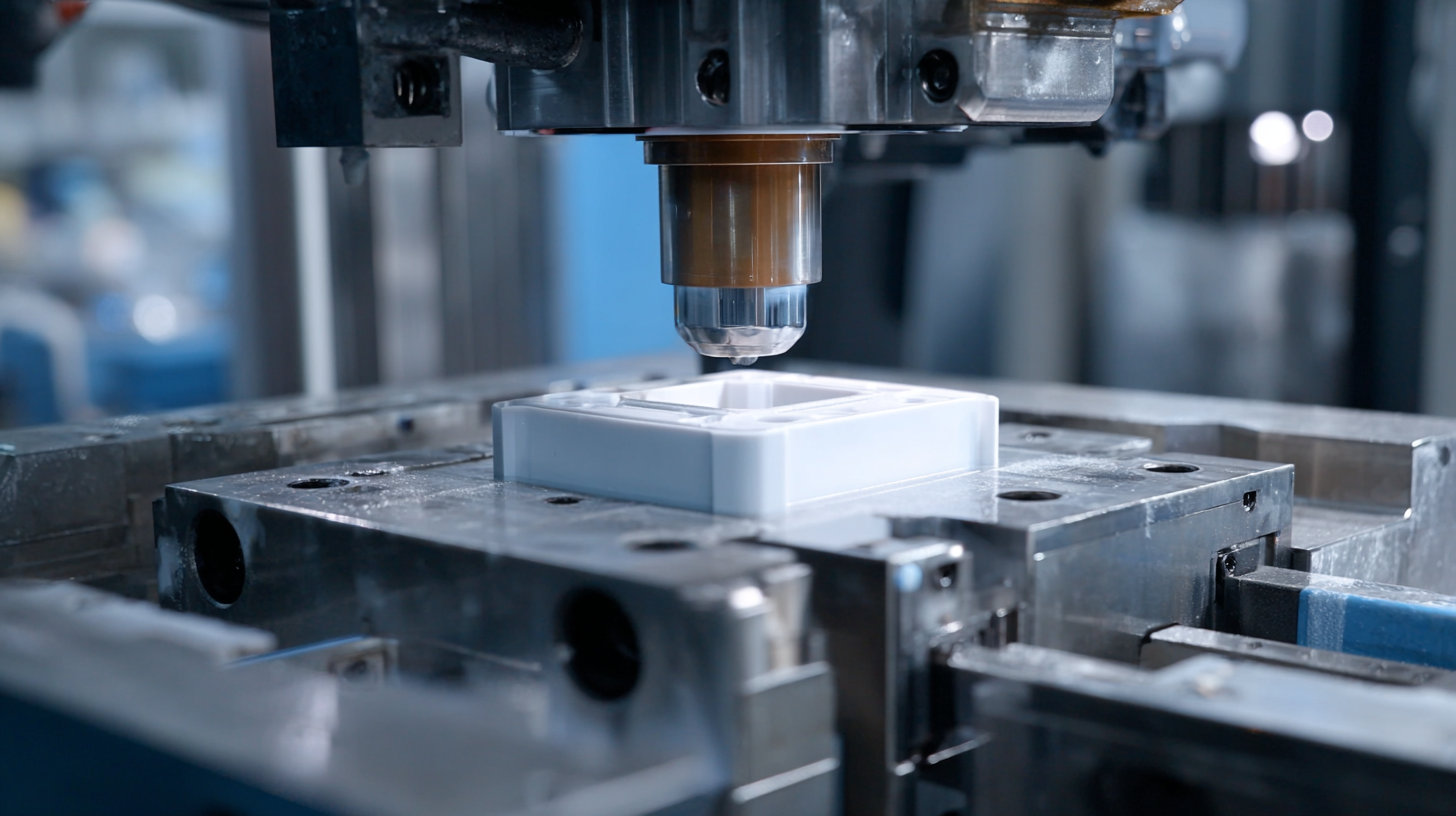

Advancements in technology have revolutionized product molding operations, significantly enhancing production efficiency. By implementing automated machinery and sophisticated software solutions, manufacturers can streamline their processes, resulting in faster turnaround times and reduced labor costs. Smart sensors and real-time data analytics allow for precise monitoring of production variables, enabling quick adjustments to maintain optimal conditions and minimize material waste. This technology not only improves throughput but also ensures consistent quality in the final products.

Moreover, integrating cutting-edge techniques such as 3D printing and CNC machining into the molding process can further expedite production cycles. These technologies facilitate rapid prototyping and customization, allowing manufacturers to respond swiftly to market demands. By investing in advanced equipment and training staff to utilize these innovations effectively, companies can create a more agile production environment. This strategic approach not only boosts efficiency but also positions firms to remain competitive in a fast-evolving marketplace.

Optimizing product molding processes begins with enhancing material selection, a crucial factor that directly influences molding performance and cost-efficiency. According to a report by the Plastics Industry Association, the right choice of materials can lead to a 20% increase in production efficiency. Selecting advanced polymers with superior flow properties and thermal stability can significantly reduce cycle times, enabling manufacturers to produce more units in less time. For instance, utilizing polypropylene over traditional materials can enhance performance while maintaining a cost-effective production process.

Furthermore, a study by the Injection Molding Association revealed that the use of recycled materials can not only lower raw material costs by up to 30% but also contribute to sustainability efforts within the industry. By carefully evaluating material properties such as viscosity, density, and heat resistance, manufacturers can optimize production processes and achieve better molding outcomes. Companies leveraging data analytics to assess material performance and align with production goals have reported a 15% decrease in waste, which amplifies both efficiency and cost savings. This strategic focus on material selection ultimately drives profitability and sustains competitive advantage in the fast-evolving molding market.

This bar chart illustrates the estimated production efficiency increase percentages associated with different types of materials used in the molding process. Achieving a 30% increase in efficiency can be significantly impacted by effective material selection.

Training and empowering staff is crucial for optimizing product molding processes and can significantly enhance production efficiency by up to 30 percent. When employees are well-versed in the best practices of molding techniques, they become more adept at spotting inefficiencies and implementing solutions that streamline operations.

Structured training programs that focus on the latest molding technologies and methods can transform an average workforce into a skilled team capable of maximizing output and minimizing waste.

Furthermore, fostering a culture of continuous improvement encourages staff to take ownership of their roles. By providing them with the tools and resources they need to experiment with different molding techniques, businesses can unlock innovative practices that may lead to further efficiency gains.

Encouraging regular feedback loops and collaboration among team members allows for the sharing of insights and methods that could benefit the entire production line, creating a collaborative environment that thrives on progress and quality.

To enhance production efficiency in product molding processes, establishing continuous monitoring and feedback loops is crucial. These systems allow manufacturers to track performance metrics in real-time, ensuring that deviations from optimal production levels are immediately addressed. By integrating data analytics tools, businesses can visualize trends and identify potential bottlenecks before they escalate into serious issues. This proactive approach minimizes downtime and maximizes output.

**Tips:** One effective strategy is to implement regular performance reviews that analyze production data alongside staff feedback. This encourages a culture of improvement where team members feel empowered to suggest operational changes. Additionally, utilizing IoT devices can automate data collection, providing a consistent stream of information to refine processes dynamically.

Moreover, encouraging collaboration across departments fosters a comprehensive understanding of how different factors influence production efficiency. By sharing insights from quality control, maintenance, and supply chain teams, companies can make informed decisions that enhance the entire molding process. Regular training sessions can further ensure that all employees understand the importance of these feedback loops and are equipped to contribute to ongoing improvements.

| Process Stage | Current Efficiency (%) | Target Efficiency (%) | Improvement Strategy | Feedback Mechanism |

|---|---|---|---|---|

| Material Preparation | 75 | 85 | Implement automated material handling | Daily efficiency reports |

| Molding Process | 70 | 90 | Optimize temperature and pressure settings | Continuous monitoring sensors |

| Cooling Cycle | 65 | 80 | Improve cooling system efficiency | Weekly performance review |

| Quality Control | 80 | 95 | Increase testing frequency | Real-time data analysis |

| Packaging | 77 | 85 | Streamline packing procedures | Feedback from packaging staff |