Optimizing injection pressure is a critical factor in enhancing production efficiency across various manufacturing sectors, particularly in the plastics and automotive industries. According to a report by the American Society of Mechanical Engineers, adjustments in injection pressure can lead to production efficiency improvements of up to 20%, while also reducing cycle times by nearly 15%. Additionally, the International Association of Plastics Engineers has highlighted that precisely controlled injection pressure not only improves the quality of molded parts but also minimizes material waste, contributing to a more sustainable manufacturing process. As industries strive to meet increasing production demands and environmental standards, understanding and optimizing injection pressure becomes imperative for achieving superior operational performance and cost-effectiveness.

Understanding injection pressure is crucial for optimizing production efficiency in various manufacturing processes. Injection pressure directly influences the quality of the product and the speed of production. According to the latest industry report by the International Plastics Association, optimizing injection pressure can increase production efficiency by up to 30%. Proper injection pressure ensures that the material fills the mold uniformly, reducing defects and minimizing waste.

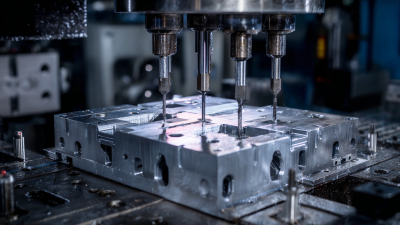

To achieve optimal injection pressure, it's essential to monitor variables such as temperature and viscosity of the materials used. Implementing a closed-loop control system can help maintain consistent pressure throughout the injection cycle. Moreover, many industry experts recommend conducting regular maintenance on injection molding machines to avoid pressure fluctuations, which can lead to operational inefficiencies.

**Tips:** Regularly calibrate your injection molding equipment to ensure accurate pressure readings. Additionally, conducting trial runs with different pressure settings can help identify the sweet spot that maximizes both speed and quality of production. Consider utilizing real-time monitoring tools to analyze pressure data, allowing for immediate adjustments and improvements in the production process.

| Parameter | Optimal Range | Impact on Production Efficiency | Recommended Practices |

|---|---|---|---|

| Injection Pressure (Bar) | 80-120 | Optimized molded parts, reduced cycle time | Regular calibration of pressure settings |

| Cycle Time (Seconds) | 30-60 | Increased throughput, minimized downtime | Optimize cooling and heating times |

| Material Temperature (°C) | 210-250 | Consistent quality, reduced defects | Monitor temperature profiles regularly |

| Screw Speed (RPM) | 50-100 | Improved melt consistency, enhanced mixing | Adjust screw settings according to material |

| Back Pressure (Bar) | 5-15 | Better melt homogenization, fewer bubbles | Adjust back pressure for specific applications |

The optimization of injection pressure is crucial for maximizing production efficiency in various manufacturing processes, particularly in industries such as plastics and pharmaceuticals. Several key factors influence the injection pressure, including material viscosity, mold temperature, and the design of the injection system. Higher material viscosity typically requires increased injection pressures to ensure proper flow into the mold, whereas lower viscosities can enable more efficient injection at reduced pressures.

Mold temperature plays a significant role as well. Higher temperatures can decrease material viscosity, allowing for faster filling without the need for excessive pressure. Conversely, if the mold temperature is too low, the higher viscosity of the material may lead to incomplete filling and defects. Furthermore, the design of the injection system, including the nozzle diameter and the length of the injection path, significantly impacts pressure requirements. A well-designed system minimizes resistance and optimizes flow, thereby enhancing production efficiency. Addressing these factors diligently can lead to improved output quality and reduced cycle times, ultimately benefiting overall production.

Effective measurement and monitoring of injection pressure are critical for optimizing production efficiency in various manufacturing processes, particularly in injection molding and related fields. According to the Plastics Industry Association, an optimal injection pressure can reduce cycle times by up to 30% and significantly improve product quality. To achieve these results, manufacturers must employ precision monitoring techniques, such as using pressure transducers and data logging systems, which provide real-time feedback on injection pressure during the entire cycle.

Implementing advanced monitoring systems enables operators to identify pressure variations that may indicate issues with the injection process. For instance, research published in the Journal of Manufacturing Science and Engineering highlights that a variation of even 10% in injection pressure can lead to a 15% increase in defects per batch. By integrating IoT devices and sensors into their production lines, companies can monitor injection pressure continuously, allowing for quick adjustments and minimizing downtime, thereby enhancing overall operational efficiency.

To enhance production efficiency in injection molding processes, adjusting injection pressure is crucial. The first strategy involves carefully analyzing the material used in the process. Different materials have unique viscosity characteristics, which respond differently to variations in pressure. For instance, using lower injection pressures may be effective for high-viscosity materials, allowing for smoother flow, while reducing the risk of defects. Conversely, for low-viscosity materials, higher injection pressures may be required to ensure complete filling of the mold cavity. Conducting thorough material compatibility studies can help identify the optimal pressure range.

Another critical approach is monitoring and adjusting the injection speed in conjunction with pressure. A balanced injection speed can prevent overpacking or underpacking, which directly affects the final product quality. Implementing a multi-stage injection process allows for initial low-pressure filling to minimize shear stress and avoid issues such as flash or short shots. Following this, increasing the pressure can help achieve better compaction and ensure that the mold is entirely filled. By leveraging both pressure and speed adjustments strategically, manufacturers can achieve optimal output while enhancing production efficiency.

Maintaining consistent injection pressure is critical for optimizing production efficiency in injection molding. As industry standards evolve, it's essential to adopt best practices that ensure stable operation. Cavity pressure measurement has emerged as a key indicator of molding conditions, offering predictive insights into quality outcomes. Implementing cavity pressure-based adjustments can significantly enhance the consistency of product quality, which ultimately leads to reduced scrap rates and improved cycle times.

Tips: Regular calibration of pressure sensors can help maintain accuracy. Utilize automated feedback systems to continuously monitor and adjust injection pressure in real-time. This proactive approach not only minimizes variability but also aligns with the industry trend towards more autonomous and self-correcting molding processes.

Furthermore, integrating innovative process-control software into injection molding machines can provide manufacturers with a more intuitive user interface. This allows for better oversight and management of injection parameters, improving overall operational efficiency. As technology advances, the adoption of low-pressure molding techniques may also be beneficial, allowing for greater energy efficiency and reduced wear on machinery while still delivering high-quality results.