In the ever-evolving landscape of manufacturing, the optimization of injection molding products has become a pivotal focus for companies seeking to enhance efficiency and quality in their production processes. As industries strive for competitiveness and sustainability, understanding the intricacies of injection molding can pave the way for significant advancements. This blog delves into effective strategies and tips that manufacturers can implement to streamline their injection molding operations, reduce material waste, and improve product integrity. By embracing technological advancements and fine-tuning design parameters, businesses can achieve not only higher throughput but also superior quality in their injection molding products.

Join us as we explore actionable insights aimed at maximizing both performance and output in this critical manufacturing domain.

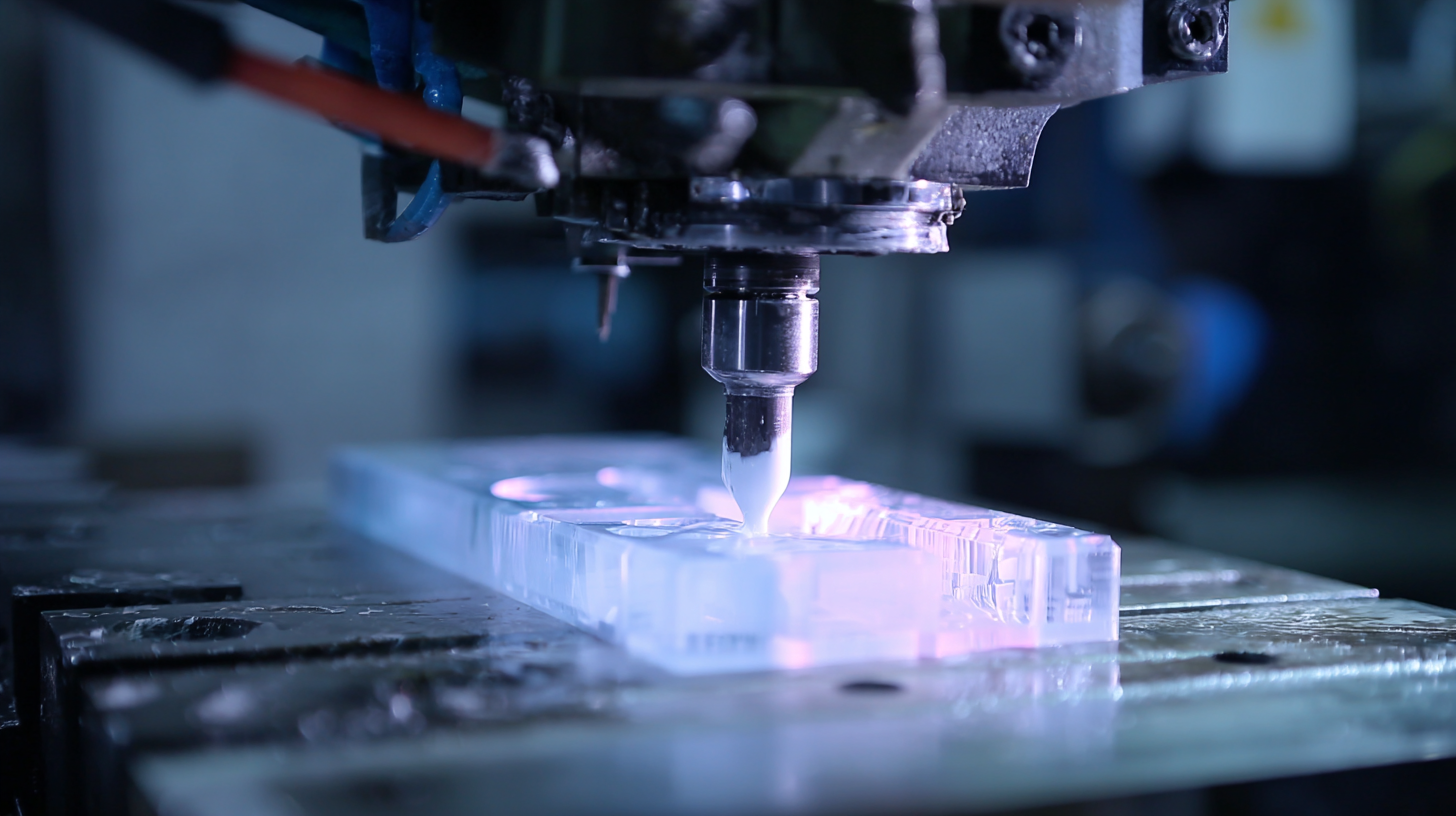

When aiming for optimal injection molding performance, understanding key design factors can significantly enhance both efficiency and product quality. One critical aspect is the selection of the right material. Choosing materials with appropriate flow characteristics ensures that they fill the mold uniformly and minimize defects. For instance, thermoplastics often allow for better flexibility and quicker cycle times, while thermosets provide superior dimensional stability.

Another essential design element is the mold geometry. Features such as wall thickness and rib design play a significant role in achieving a balanced flow of the molten material. Designers should strive for uniform wall thickness to prevent warping and stress concentrations. Additionally, incorporating features like draft angles and rounded edges can facilitate easier part removal while reducing cycle time. Together, these factors contribute to a more efficient injection molding process, leading to higher quality outputs and reduced production costs.

Selecting the right materials is a critical step in optimizing injection molding products for enhanced quality and efficiency. The choice of material directly impacts not only the performance of the final product but also the efficiency of the manufacturing process itself. For instance, engineers often consider polycarbonate for its excellent impact resistance and clarity, making it ideal for applications requiring durability and visual appeal. Similarly, selecting a high-flow polypropylene can significantly reduce cycle times, resulting in improved productivity without compromising on the finished product's integrity.

Selecting the right materials is a critical step in optimizing injection molding products for enhanced quality and efficiency. The choice of material directly impacts not only the performance of the final product but also the efficiency of the manufacturing process itself. For instance, engineers often consider polycarbonate for its excellent impact resistance and clarity, making it ideal for applications requiring durability and visual appeal. Similarly, selecting a high-flow polypropylene can significantly reduce cycle times, resulting in improved productivity without compromising on the finished product's integrity.

Furthermore, understanding the specific characteristics of materials can lead to better design choices that optimize flow and reduce defects. For example, using reinforced materials may enhance strength while allowing for thinner wall sections, thereby lowering material usage and weight. Additionally, it is crucial to consider factors such as thermal stability and chemical resistance, which can influence the molding process and the longevity of the products. By prioritizing the appropriate material selection, manufacturers can not only achieve superior product quality but also streamline operations for maximum efficiency.

When it comes to optimizing injection molding products for maximum efficiency and quality, minimizing cycle time is crucial. To achieve this, implementing advanced techniques can significantly enhance production processes. One effective approach is to utilize rapid mold cooling systems, which can expedite the cooling phase of the cycle. By maintaining optimal temperature control, you can reduce the time required for each cycle, allowing for faster production without compromising product quality.

When it comes to optimizing injection molding products for maximum efficiency and quality, minimizing cycle time is crucial. To achieve this, implementing advanced techniques can significantly enhance production processes. One effective approach is to utilize rapid mold cooling systems, which can expedite the cooling phase of the cycle. By maintaining optimal temperature control, you can reduce the time required for each cycle, allowing for faster production without compromising product quality.

Another key technique involves optimizing the injection speed and pressure. By carefully adjusting these parameters based on material flow characteristics, manufacturers can achieve faster fill times while minimizing defects. It’s essential to conduct thorough testing to find the sweet spot that balances speed with consistency, ensuring that the final products meet quality standards.

Lastly, consider investing in automation technology, such as robotics for part handling and finishing processes. Automating these post-molding steps not only reduces manual labor but also minimizes downtime between cycles. This integrated approach fosters a seamless workflow, ultimately enhancing both efficiency and product quality in the injection molding process.

In optimizing injection molding products, the implementation of robust quality control measures is crucial to ensure consistent outcomes. Quality control methodologies, like Lean Six Sigma, have been shown to minimize waste and enhance production efficiency. According to a recent study, companies employing these techniques can reduce production defects by up to 30%, resulting in significant cost savings and improved product reliability. These measures also facilitate better supplier selection and inventory control, ultimately enhancing the overall supply chain management.

To further enhance quality, integrating advanced technologies such as machine learning and artificial intelligence within the quality control processes can yield substantial benefits. AI tools can analyze large datasets to identify patterns in defects and predict potential failures, thereby enabling proactive adjustments. This approach not only improves the quality of manufacturing processes but also aligns with current trends in smart manufacturing.

Tips:

- Regularly conduct quality audits and employ statistical process control to monitor production processes.

- Leverage AI-driven analytics to continuously assess and improve quality control practices.

- Educate your team on quality standards and best practices to foster a culture of quality throughout your organization.

To achieve peak production efficiency in injection molding, optimizing machine settings is crucial. First, focusing on temperature control can significantly impact the quality of the final product. Ensuring that the nozzle, barrel, and mold temperatures are dialed in according to the material specifications helps in achieving uniform flow and reducing cycle times. Additionally, maintaining appropriate cooling times is essential; if the cooling phase is too short, it may lead to warping or surface defects, while excessive cooling can unnecessarily extend production cycles.

Another vital aspect of enhancing machine settings is the adjustment of injection speed and pressure. Optimizing these parameters ensures that the material fills the mold completely without creating air bubbles or causing flash. A gradual increase in injection speed often allows for better filling and prevents premature solidification of the material. Furthermore, balancing hold pressure and time is also important; ensuring the part maintains optimal shape during cooling significantly improves overall quality. By meticulously fine-tuning these machine settings, manufacturers can not only enhance efficiency but also elevate the quality of their injection-molded products.