In the intricate world of injection molding, achieving optimal mold pressure is crucial for enhancing product quality and operational efficiency. Mold pressure directly influences the filling of the mold cavity, the flow characteristics of the molten material, and the overall integrity of the final product. However, many manufacturers overlook the significance of carefully managing this critical parameter, leading to defects such as warping, sink marks, and inconsistent surface finishes.

In the intricate world of injection molding, achieving optimal mold pressure is crucial for enhancing product quality and operational efficiency. Mold pressure directly influences the filling of the mold cavity, the flow characteristics of the molten material, and the overall integrity of the final product. However, many manufacturers overlook the significance of carefully managing this critical parameter, leading to defects such as warping, sink marks, and inconsistent surface finishes.

This article aims to uncover the secrets behind optimal mold pressure management, offering practical insights and strategies that professionals can implement in their production processes. By understanding the interplay between mold pressure and various processing factors, manufacturers can significantly improve the quality of their products while minimizing waste and production costs. Join us as we delve into the essential techniques and best practices that will help you master mold pressure for exceptional injection molding results.

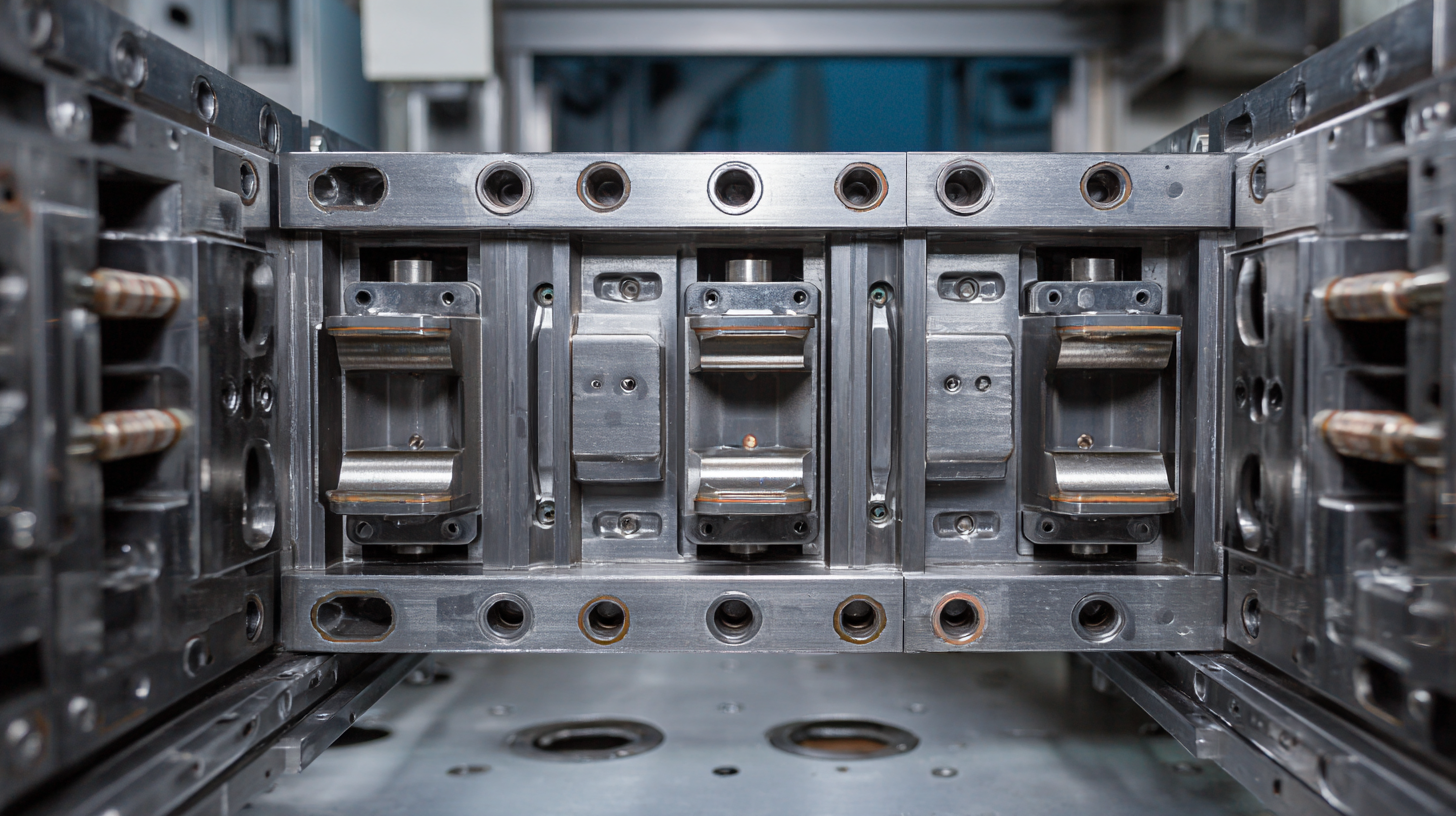

Injection molding is a widely utilized manufacturing process that allows for the efficient production of high-quality plastic components. This technique involves forcing molten plastic into a mold, where it cools and solidifies to form the desired shape. According to the American Society of Plastics Engineers (ASPE), injection molding accounts for approximately 30% of the global plastics market, highlighting its significance in producing a vast array of products, from automotive parts to consumer goods. The precision and repeatability offered by injection molding make it essential for industries requiring tight tolerances and complex geometries.

One critical factor that directly influences the quality of end products is mold pressure. The injection molding process relies on optimal mold pressure to achieve consistent flow and proper filling of the mold. Recent industry reports indicate that maintaining an ideal pressure range can reduce defects by up to 25%, significantly enhancing product performance and durability. By fine-tuning mold pressure settings, manufacturers can minimize issues such as short shots, sink marks, and warping, which not only improves the quality of the final product but also reduces waste and production costs. Emphasizing the importance of mold pressure in injection molding is vital for organizations looking to optimize their manufacturing processes and deliver superior products.

Optimal mold pressure in injection molding is crucial for achieving high-quality products. Several key factors define this ideal pressure, including the type of material used, the geometry of the mold, and the specific requirements of the final product. Understanding these factors allows manufacturers to adjust their processes accordingly, leading to fewer defects and improved mechanical properties.

**Tips:** When determining optimal mold pressure, always conduct trials with varying pressure settings to see which yields the best results. Additionally, consider using pressure sensors in the mold to monitor real-time conditions and make necessary adjustments dynamically.

Moreover, measurements play a vital role in defining optimal mold pressure. This involves not only the direct application of pressure but also the assessment of flow rates, cooling times, and temperature fluctuations. Precise monitoring ensures that the material fills the mold uniformly, minimizing issues such as warping or incomplete filling.

**Tips:** Employ advanced simulation software to model fluid dynamics within the mold. This can provide insights into how changes in pressure affect the flow and distribution of the material, leading to more informed decisions in the manufacturing process.

Mold pressure plays a critical role in the injection molding process, directly influencing the integrity and performance of the final product. By optimizing mold pressure, manufacturers can ensure the material fills the mold cavity completely and uniformly, which is essential for preventing defects such as sink marks, voids, and dimensional inaccuracies. The correct application of mold pressure allows for the precise replication of the mold's features in the finished product, enhancing both its structural integrity and aesthetic appeal.

Moreover, effective management of mold pressure contributes to the overall efficiency of the injection molding process. High and consistent mold pressure can minimize cycle times and improve throughput without compromising product quality. Additionally, understanding the interplay between mold pressure, temperature, and material viscosity enables engineers to fine-tune the injection molding conditions to achieve superior performance characteristics. This intricate balance is essential for producing items that meet stringent quality standards, thereby reinforcing the importance of mold pressure in achieving excellence in injection molded products.

| Mold Pressure (MPa) | Product Quality Rating (1-10) | Cycle Time (seconds) | Defect Rate (%) | Material Used |

|---|---|---|---|---|

| 50 | 9 | 30 | 2 | Polypropylene |

| 60 | 8 | 25 | 3 | ABS |

| 70 | 7 | 28 | 5 | Polycarbonate |

| 80 | 8.5 | 27 | 4 | Nylon |

| 90 | 9.5 | 26 | 1 | Polystyrene |

Achieving optimal mold pressure in injection molding processes is crucial for enhancing product quality and reducing defects. According to a 2022 industry report from the Plastics Technology Association, maintaining precise mold pressure can minimize issues such as warping and shrinkage, which can lead to significant cost savings in production. Techniques such as implementing real-time pressure monitoring systems and utilizing advanced simulation software allow manufacturers to fine-tune their processes, ensuring consistent quality and improved output.

Another effective technique for managing mold pressure includes optimizing the material flow through careful selection of gate sizes and runner geometries. A study by the Society of Plastics Engineers indicates that adjusting gate sizes can enhance the filling process, achieving a uniform pressure distribution within the mold cavity. Furthermore, temperature control is essential; maintaining consistent temperatures aids in achieving the desired viscosity of the molten polymer, facilitating optimal flow while reducing the likelihood of defects related to pressure fluctuations. By employing these techniques, manufacturers can unlock the potential for superior product quality and operational efficiency in their injection molding processes.

In the realm of injection molding, mold pressure is a crucial factor that significantly influences the quality of the final product. Recent case studies reveal that variations in mold pressure can lead to distinct outcomes in product integrity and surface finish. For instance, a study conducted by the Society of Plastics Engineers indicated that operating at optimal mold pressures can reduce the occurrence of defects, such as warping and sink marks, by up to 30%. Furthermore, maintaining consistent pressure throughout the cycle enhances dimensional accuracy, with reports showing that deviations can result in a 15-20% increase in product rejection rates.

Another case study highlighted a manufacturer’s adjustment of mold pressure during production runs, leading to improved mechanical properties of the final parts. By fine-tuning the mold pressure, the tensile strength of the products increased by approximately 25%, thereby improving their performance in demanding applications. The data underscores the importance of precise mold pressure management, aligning with findings from the American Society for Testing and Materials, which suggest that optimal processing conditions are key to achieving superior product quality in injection molding operations.