Mold pressure plays a critical role in the manufacturing industry, particularly in 2026. As an expert in this field, Dr. Emily Stanton once stated, "Understanding mold pressure is essential for creating high-quality products." This statement highlights its significance in production processes.

Mold pressure influences how materials flow into molds. Variations can lead to defects that affect the final product's quality. Many manufacturers struggle to maintain consistent mold pressure. This inconsistency can result in wasted materials and increased production times. For example, a slight change in pressure can cause misalignment in molded parts.

Additionally, advancements in technology aim to improve mold pressure monitoring. However, industry leaders acknowledge that challenges remain. They urge continuous study and adaptation to harness the full potential of mold pressure. Despite progress, many companies can still optimize their processes further. Understanding this factor better can drive innovation and enhance production efficiency in manufacturing.

Mold pressure is crucial in manufacturing. It plays a significant role in determining the quality of the final product. High mold pressure can lead to defects, while low pressure may cause incomplete filling. Achieving the right balance is essential for product consistency.

A critical factor is the viscosity of the material used. The pressure applied must account for this property. If the material is too thick, it might not fill the mold properly. Conversely, thinner materials may lead to excess pressure buildup. Monitoring these aspects is vital.

Tip: Regularly calibrate your equipment. Mismatched settings can create imbalances in pressure.

Temperature also affects mold pressure. A cooler environment might thicken materials, causing pressure inconsistencies. It can also slow down the curing process. Maintaining an optimal temperature helps prevent fluctuations in pressure.

Tip: Use thermal imaging to monitor temperature variations. This can help identify hotspots that may lead to issues.

Evaluate your mold design too. Complex geometries can create pressure challenges. Simplifying the design may reduce these risks and improve efficiency. Always seek ways to refine your processes. Reflect on what works and what needs improvement.

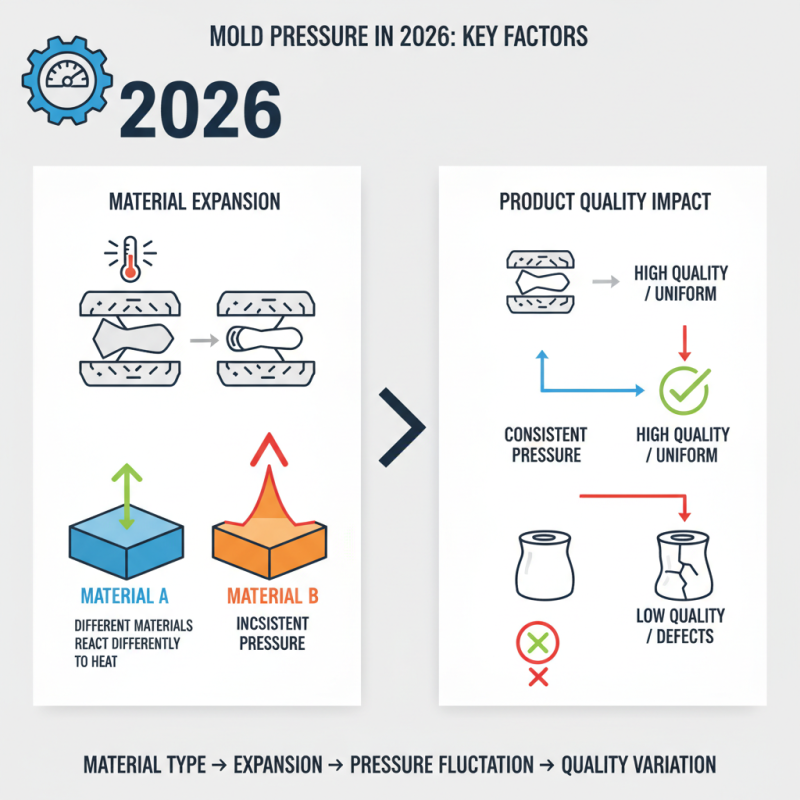

Mold pressure plays a crucial role in manufacturing processes, especially in molding operations. In 2026, various factors influence this pressure significantly. One major aspect is the material used in the molds. Different materials expand differently under heat. This impact on pressure can lead to inconsistencies in product quality.

Temperature variations during the molding process also affect mold pressure. Fluctuations can create unwanted pressure changes. Monitoring these temperatures is essential to maintain product integrity. Operators should develop routines to check these levels regularly. A neglected temperature setting can lead to defects that are hard to fix later.

**Tips:** Always calibrate equipment to ensure accurate readings. Keep a log of temperature changes for analysis. Consider training staff to identify signs of excessive pressure. Identifying problems early can save time and resources. In an industry where precision is vital, small oversights can snowball into significant issues. Consistency in monitoring can lead to better outcomes in the long run.

Mold pressure has become a crucial technique in various manufacturing sectors. In 2026, several types of manufacturing are leading the way. These sectors rely heavily on mold pressure to create precise and efficient products.

Injection molding is a prominent method using mold pressure. This process allows manufacturers to produce complex shapes in plastics. It often leads to less waste and faster production rates. However, the initial setup can be costly and require ongoing adjustments.

Another significant area is metal casting. Here, mold pressure techniques ensure the quality of metal components. This method can improve strength and reduce defects in products. Yet, it requires careful monitoring and skills. The balance between innovation and challenges creates a dynamic manufacturing environment.

This chart displays the top types of manufacturing industries utilizing mold pressure techniques in 2026, showcasing their respective production volumes in thousands of units.

Mold pressure plays a crucial role in manufacturing processes. It affects the quality and uniformity of the final product. In 2026, maintaining optimal mold pressure is challenging. According to industry reports, 25% of production issues stem from improper pressure levels. This can lead to defects, increased waste, and higher costs.

Temperature fluctuations can cause mold pressure variations. When the temperature is not stable, it affects material viscosity. This inconsistency can result in incomplete filling of molds. Specialists noted that adopting real-time monitoring systems can help manage these pressures effectively. Additionally, training staff on the nuances of pressure adjustments can mitigate risks.

Mold design also influences pressure management. Complex designs may create backpressure, complicating the manufacturing process. Not all teams are equipped to handle these challenges. Research suggests that 30% of manufacturers report difficulties in adjusting to mold requirements. Continuous improvement and adaptation are essential for success in this evolving landscape.

In 2026, mold pressure remains a pivotal factor in manufacturing processes. It influences production quality significantly and shapes the outcome of various products. Higher mold pressure can enhance the detail and strength of the final output. However, achieving the right level of pressure is challenging. Too much pressure can lead to defects.

The trend toward automation will increase the precision of mold pressure applications. Sensors and smart technologies will play a crucial role. These innovations allow for real-time adjustments. Visual alerts indicate if pressure levels are optimal. However, not all manufacturers are ready for this change. Some might struggle with integrating advanced technologies into their systems.

Recycling processes also see mold pressure becoming increasingly important. Undoubtedly, using recycled materials comes with challenges. They often require different pressure settings. This can lead to inconsistencies in product quality. For many, finding the right balance will require testing and tweaking. Adaptation is essential but can be a long road.