In today’s fast-paced manufacturing environment, maximizing efficiency is paramount for staying competitive, and one of the most promising methods to achieve this is through low pressure injection techniques. These innovative approaches not only enhance production speed but also improve the quality of the finished products.

Low pressure injection allows for a more controlled flow of materials, thereby reducing waste and minimizing defects that often occur at higher pressures. Furthermore, this technique can lead to significant cost savings by utilizing less energy and raw materials while maintaining excellent precision in the injection process.

As industries increasingly focus on sustainable practices, understanding how to leverage low pressure injection becomes essential for manufacturers aiming to optimize their operations.

In this article, we will explore various strategies and best practices to effectively implement low pressure injection techniques, helping businesses streamline their processes and achieve greater efficiency.

Low pressure injection techniques are revolutionizing the manufacturing and production sectors by enhancing operational efficiency while minimizing waste. By utilizing a lower injection pressure, these methods reduce cycle times and decrease energy consumption, creating more sustainable manufacturing processes. This is particularly beneficial in industries where precision and speed are crucial, enabling manufacturers to improve their output without compromising quality.

Incorporating low pressure injection techniques not only fosters operational efficiency but also supports a greener approach to manufacturing, effectively aligning productivity with sustainability.

Low pressure injection techniques have gained considerable traction in various industries, particularly in molding applications, due to their distinct advantages over traditional high pressure methods. According to a report by the Society of Plastics Engineers, low pressure injection can reduce energy consumption by approximately 30% compared to conventional methods. This efficiency translates not only into lower operational costs but also into a smaller carbon footprint, making it an attractive option for environmentally conscious manufacturers.

In addition to energy savings, low pressure injection reduces the risk of defects in molded parts. A study conducted by the American Injection Molding Institute highlighted that the stress levels in parts produced using low pressure techniques are significantly lower. Parts produced under these conditions exhibit enhanced dimensional stability and superior surface quality. This advancement allows for a more versatile product range and can diminish scrap rates by about 20%, effectively improving the yield and productivity of the manufacturing process. By opting for low pressure injection techniques, manufacturers open the door to greater efficiency and quality in their production lines.

This chart illustrates the efficiency metrics of Low Pressure Injection techniques compared to traditional methods. It highlights significant advantages such as reduced cycle time, lower material waste, decreased energy consumption, and shorter setup time.

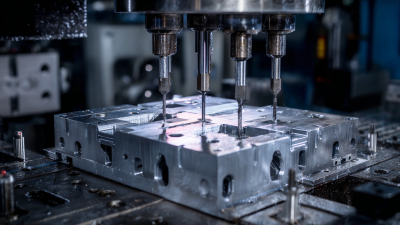

Low pressure injection techniques have gained significant attention in various advanced industries due to their efficiency and cost-effectiveness. To achieve success in low pressure injection, selecting the right equipment and tools is crucial. Essential components typically include precision injectors designed to minimize material wastage while maximizing output quality. Moreover, the use of specialized molds that can withstand low pressure without compromising the structural integrity of the final product plays a vital role in ensuring consistency and reliability.

Low pressure injection techniques have gained significant attention in various advanced industries due to their efficiency and cost-effectiveness. To achieve success in low pressure injection, selecting the right equipment and tools is crucial. Essential components typically include precision injectors designed to minimize material wastage while maximizing output quality. Moreover, the use of specialized molds that can withstand low pressure without compromising the structural integrity of the final product plays a vital role in ensuring consistency and reliability.

In the context of global innovation, countries like China are rapidly advancing in advanced industries, raising the competitive stakes for others. The shift towards automation and improved manufacturing techniques, particularly in metal injection molding, highlights the technological investments being made. By focusing on essential equipment and tools, companies can streamline their production processes and enhance their market position, ultimately leveraging low pressure injection techniques to meet growing demand while adapting to the innovative landscape driven by global players.

Low pressure injection techniques have become increasingly popular in various manufacturing sectors due to their ability to enhance workflow and efficiency. According to a study by the Society of Plastics Engineers, implementing low pressure injection methods can reduce material waste by up to 30%, a significant factor for companies aiming to improve their sustainability practices. By utilizing advanced mold designs and optimizing process parameters, manufacturers can streamline their operations while maintaining high product quality.

To maximize efficiency, it is essential to adopt best practices in the workflow. Training staff to understand the nuances of low pressure injection techniques can also play a crucial role; a report from the International Journal of Production Research indicates that properly trained personnel can improve cycle times by up to 20%. Additionally, integrating real-time monitoring systems can help identify bottlenecks and improve maintenance schedules, leading to a more responsive production environment. These practices contribute to a smoother workflow, ultimately driving profitability and competitiveness in the market.

| Technique | Efficiency (%) | Cycle Time (min) | Material Costs ($) | Recommended Applications |

|---|---|---|---|---|

| Technique A | 85% | 15 | 200 | Automotive Parts |

| Technique B | 90% | 12 | 150 | Consumer Products |

| Technique C | 75% | 18 | 250 | Electronics |

| Technique D | 80% | 14 | 180 | Medical Devices |

Low pressure injection techniques are becoming increasingly popular in various manufacturing processes due to their ability to reduce material waste and energy consumption. However, common issues can hinder their efficiency if not addressed properly. One of the primary concerns is inconsistent material flow, which can result from improper equipment calibration or blockages in the injection system. Regular maintenance and thorough inspection of the machinery can help identify and rectify these issues promptly.

Another frequent problem is air entrapment in the injection mold, which can lead to defects in the final product. To troubleshoot this, operators should ensure that the injection process allows for proper venting. Incorporating venting channels in molds and adjusting the injection speed can facilitate better air evacuation. Furthermore, monitoring the temperature of both the material and the mold is crucial, as temperature inconsistencies can affect viscosity and flow rate, ultimately impacting the overall quality of the output. By addressing these common issues through proactive measures, manufacturers can enhance the efficiency of low pressure injection processes.