Mastering injection molding techniques can seem daunting for beginners. This process is crucial in various industries, from automotive to consumer goods. Beginners often face challenges, but understanding the basics is essential.

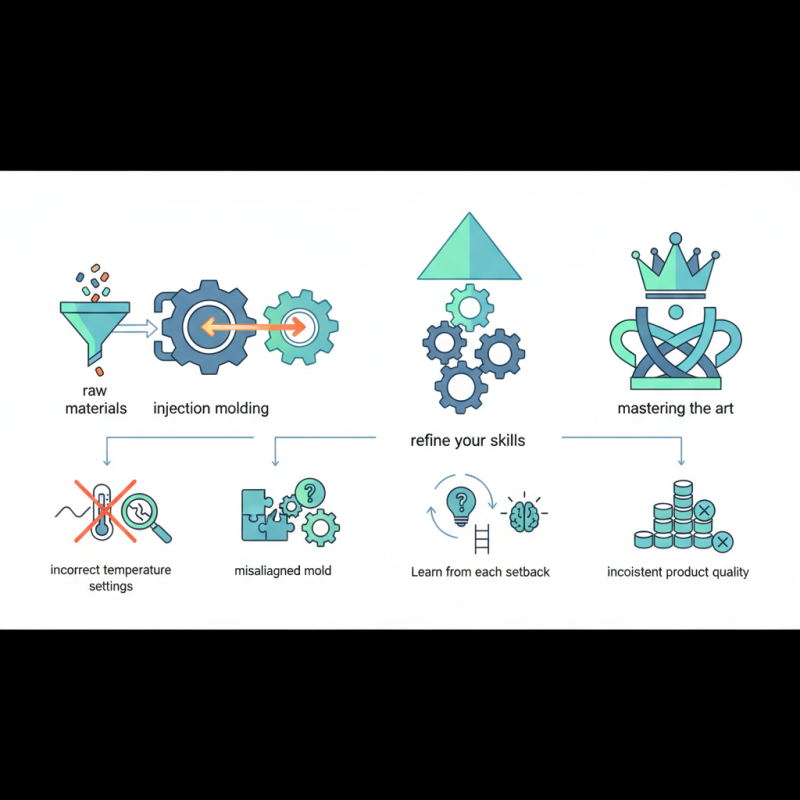

Injection molding involves turning raw materials into precise parts. Each step, from material selection to machine setup, requires careful attention. Small mistakes can lead to significant flaws. For instance, incorrect temperature settings can cause defects in the final product.

As you refine your skills, be prepared for trial and error. Experimentation is key to success in injection molding. Learn from each setback, whether it’s a misaligned mold or inconsistent product quality. Embrace these challenges. They pave the way to becoming proficient in the art of injection molding.

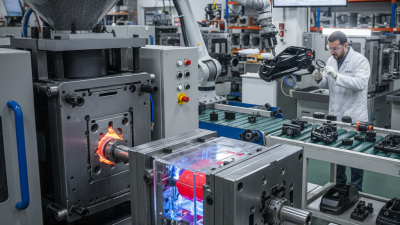

Injection molding is a fascinating technique used to create a wide variety of plastic products. For beginners, understanding the basics is crucial. This method involves melting plastic pellets and injecting them into a mold. Once cooled, the mold is opened, revealing the finished part. It sounds simple, but mastering the technique takes practice.

Beginners often struggle with several aspects. One common issue is achieving consistent temperature controls. If the plastic is too hot or cold, defects may occur. Another point to consider is the selection of the right mold design. A poorly designed mold can lead to incomplete parts or excessive waste. Learning through trial and error is part of the process.

Practice makes perfect. Explore various injection molding machines and find one that suits your needs. Experimentation allows you to uncover hidden challenges. Every mistake is an opportunity to learn. Take the time to reflect on what went wrong. This self-assessment is essential for growth. Understanding these intricacies will pave the way for future success.

Mastering injection molding requires essential equipment and tools. A reliable injection molding machine is the centerpiece of your workshop. This machine helps shape plastic materials into desired forms. Look for features like consistent temperature control and adjustable pressure settings. These aspects are crucial for achieving precision.

In addition to the machine, you'll need molds. They come in various shapes and sizes, influencing the final product's quality. Choose materials that withstand high temperatures. Steel molds are durable but expensive, while aluminum molds are cost-effective for beginners. Don't forget about auxiliary tools like cooling systems, which ensure products solidify properly.

Safety gear should not be overlooked. Protective gloves and goggles are necessary when handling materials. Some beginners underestimate this part, which can lead to accidents. Workspaces should be organized to avoid spills and hazards. Reflection on past mistakes can guide you to create a safer environment. With the right tools in place, you can begin your journey in injection molding while ensuring safety and efficiency.

Injection molding is an exciting process. For beginners, understanding the basics is crucial. This technique involves injecting molten material into a mold. The result is precise and complex shapes. Start with selecting the right materials. Thermoplastics and thermosetting plastics are common choices. Each has unique properties and applications. Choose wisely based on your project needs.

Next, focus on the mold design. It should accommodate the material's cooling and solidification. Designing a mold is challenging. Flaws can lead to defects in the final product. Pay attention to draft angles and venting. These details impact the production quality. Once the mold is ready, set up the injection machine. Control factors like temperature and pressure carefully. Watch for inconsistencies; they can ruin production.

Finally, practice makes perfect. It's common to face challenges. Maybe the parts don’t fit, or the finish isn't smooth. Analyze the results and adjust your approach. Learning from mistakes is part of mastering injection molding techniques. Keep experimenting and refining your skills. Progress takes time and patience, but persistence pays off. Embrace the journey!

Injection molding is a complex process that often presents challenges, especially for beginners. A significant issue is achieving consistent quality. Variations in temperature and pressure can lead to defects like warping or short shots. According to a recent industry report, nearly 20% of molded parts fail quality tests due to such inconsistencies. Understanding the right temperature range for different materials is critical.

Tip: Regularly calibrate your injection molding machine to ensure optimal performance. Keep records of temperature settings and monitor any variations closely.

Another common hurdle is selecting the appropriate materials. Not all plastics are created equal. Each type has its own melting point and flow behavior. Choosing the wrong one can lead to production delays. A survey indicated that about 30% of projects face significant setbacks due to material selection mistakes.

Tip: Conduct small-scale tests with various materials to see how they perform. Document your findings. Continuous learning will help you make informed choices.

A third challenge is mold design. Complex molds can create complications like increased cycle times and higher costs. Inexperienced mold makers may overlook aspects such as draft angles, which can cause ejection difficulties. Reflect on the designs submitted for your projects; they may need enhancements.

Tip: Collaborate with experienced mold designers. Their insights could help streamline production and reduce errors.

Injection molding is a fascinating field, but safety must always come first. According to industry reports, nearly 30% of workplace accidents in manufacturing involve handling machinery. Awareness of these risks is essential for beginners. Always wear personal protective equipment (PPE). This includes gloves, goggles, and hard hats. Poor safety practices can lead to serious injuries.

Proper training is crucial. A report states that companies with comprehensive training programs see a 50% reduction in accidents. Beginners should seek mentors or training sessions. Understanding equipment operation is fundamental. Keep the work area clean to avoid trip hazards. Maintain machinery to prevent malfunctions. Regular inspections can catch issues before they lead to accidents.

Good practices also involve understanding materials. Different polymers have unique handling requirements. Ensure proper ventilation when working with certain materials, as fumes can be harmful. Recognizing these nuances sets the foundation for safe operations. It’s important to continually reflect on safety protocols. Mistakes can happen, and learning from them is vital for growth in injection molding.