In the realm of modern manufacturing, machine injection stands as a cornerstone of efficiency and precision. Renowned industry expert Dr. Emily Chen once stated, "Machine injection transforms the way we design and produce." This underscores its vital role in enhancing productivity.

Machine injection allows manufacturers to produce complex parts with remarkable accuracy. It streamlines workflows, reducing lead times. Companies now rely on this technology to meet increasing demand. However, some still struggle with adoption. Transitioning traditional methods to machine injection comes with challenges and requires careful planning.

Furthermore, while machine injection is essential, it is not without its imperfections. The technology demands significant investment and training. Many firms hesitate, fearing potential downtime or initial failures. These hurdles need attention, as they can impact long-term benefits. Embracing machine injection is not just about tech—it requires a mindset shift.

Machine injection plays a pivotal role in modern manufacturing processes. This technique has transformed how products are developed and produced. According to recent industry reports, around 30% of manufacturing costs are attributed to inefficient methods. Machine injection can significantly reduce these costs by streamlining production cycles and minimizing waste.

In sectors like automotive and electronics, precision is crucial. Machine injection allows for high-quality components with exact tolerances. A study from the Manufacturing Institute found that companies using advanced injection techniques reported a 25% increase in productivity. This data highlights the importance of adopting innovative processes to stay competitive.

**Tips:** To optimize your machine injection process, ensure regular maintenance is prioritized. Small malfunctions can cause major setbacks. Additionally, train your team on the latest technologies, as skilled operators can identify improvements.

However, the reliance on machine injection isn't without challenges. Some manufacturers struggle to adapt to rapid technological shifts. For example, integrating new materials may require significant adjustments. It's essential to remain flexible and open to change, otherwise, companies risk falling behind.

The world of manufacturing has undergone dramatic changes over the last few decades. Machine injection technology has played a pivotal role in this transformation. Initially, it was a simple and manual process, often slow and inefficient. Over time, automation entered the scene. Machines began to inject materials with precision, reducing waste and improving product quality significantly.

The evolution did not stop there. Recent advancements have introduced sophisticated software and robotics. These innovations enhance the control of injection parameters, leading to faster production times. However, with these enhancements come challenges. Workers need new skills to operate advanced machines. This shift can create gaps in the workforce, requiring continuous training and adaptation.

Despite the benefits, there are areas needing reflection. Automation can lead to job displacement, raising questions about the future of work. Manufacturers must balance efficiency with the need for a skilled labor force. Plus, the environmental impact of machine injection processes is still under scrutiny. Striving for sustainability remains a challenge that the industry must confront head-on.

Machine injection systems have revolutionized modern manufacturing. The technology allows for high precision and efficiency. According to recent industry reports, companies utilizing machine injection can see productivity increases of up to 30%. This is due to reduced cycle times and fewer defects in production.

Implementing these systems also leads to cost savings. Automating the injection process reduces labor costs significantly. A study highlighted that manufacturers could save around 20% in operational costs after transitioning to machine injection. Furthermore, the systems are designed to minimize material waste. Some factories report waste reduction rates exceeding 50% when using these advanced methods.

However, there are challenges to consider. Initial setup costs for machine injection can be high. Smaller manufacturers might struggle to invest. There is also a learning curve involved. Training staff to operate the new technology effectively takes time. This need for adaptation can lead to short-term disruptions in production. The benefits, though significant, require careful planning and consideration.

| Benefit | Description | Impact on Production | Cost Efficiency |

|---|---|---|---|

| Increased Precision | Machine injection systems enhance the precision of manufacturing processes, reducing waste and rework. | Higher quality output leading to fewer defects. | Lower scrap rates minimizes production costs. |

| Faster Production Cycles | Automation through machine injection allows for quicker production times and shorter cycle durations. | Increased throughput with the ability to meet higher demand. | Reduced labor costs and overtime expenses. |

| Flexibility in Design | Machine injection allows for easy changes in design and rapid prototyping. | Facilitates innovation and adaptation to market changes. | Less investment in new molds or tools. |

| Energy Efficiency | Modern machines are designed to optimize energy consumption. | Lower operational costs and reduced environmental impact. | Long-term savings on energy bills. |

| Enhanced Safety | Automated systems reduce the risk of accidents and injuries in the workplace. | Promotes a safer working environment for employees. | Potentially lower insurance and liability costs. |

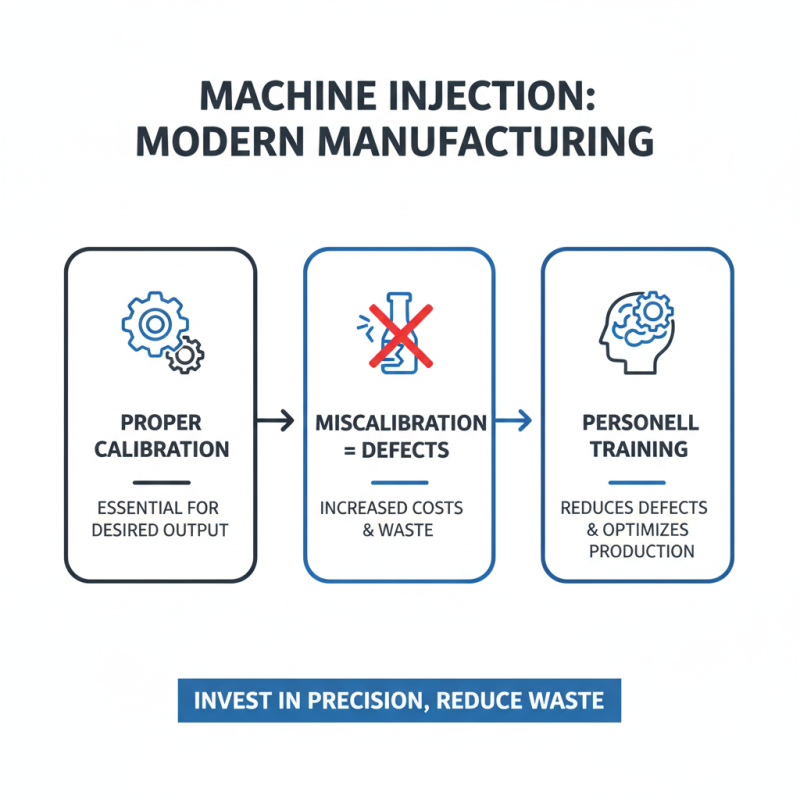

Machine injection has become a vital part of modern manufacturing. However, it comes with its challenges. Proper calibration is essential for achieving the desired output. A slight miscalibration can lead to defects. These imperfections can escalate costs and waste materials. It’s crucial to invest time in training personnel on equipment.

Tips: Regular maintenance checks can prevent issues. Schedule these checks to ensure everything runs smoothly.

Another challenge is the need for specific materials for different projects. Sourcing these materials can be time-consuming. Not all suppliers provide high-quality options. Evaluating suppliers based on consistent quality is necessary. Communication with suppliers can help in finding suitable solutions quickly.

Tips: Creating a reliable database of suppliers may save time in the future. This can streamline the sourcing process. Regular reviews of supplier performance can optimize this aspect of manufacturing.

Overall, navigating challenges in machine injection requires a balance of skill and resource management. Each step in the process deserves careful consideration to ensure efficiency and quality.

Machine injection has become a cornerstone in modern manufacturing. Its ability to produce complex parts quickly drives efficiency. As industries evolve, specific trends emerge that shape future production practices. One key trend is the shift towards automation. Automated machine injection systems can significantly reduce human error. However, this may lead to challenges in workforce adaptation. Employees need retraining for new technologies, which can be a resource-intensive process.

Another notable trend is the growing focus on sustainability. Manufacturers are increasingly seeking eco-friendly materials for injection processes. This creates opportunities for innovation and efficiency. However, sourcing these materials can be difficult and costly. Not all manufacturers are ready for this shift. Companies must carefully assess their capabilities and market demands.

Data analytics is also transforming machine injection. Real-time insights enhance production monitoring. Predictive maintenance can minimize downtime. Yet, reliance on data brings its own set of issues. Misinterpretation can lead to faulty strategies. Balancing technology and human insight is crucial. The future of machine injection is bright, but not without hurdles.