In the ever-evolving landscape of manufacturing, optimizing production processes while managing costs is essential for maintaining a competitive edge. One effective approach that has gained traction in recent years is low pressure injection molding. This technique has been reported to significantly enhance efficiency and reduce material waste, making it a viable option for various industries, from automotive to consumer goods. According to a recent market analysis by Smithers Pira, low pressure injection molding can lower energy consumption by up to 30% compared to traditional high-pressure methods, resulting in both economic and environmental benefits.

As the demand for precision components continues to rise, manufacturers are increasingly turning to low pressure injection molding to meet these needs without compromising quality. This process not only minimizes the risk of defects and enhances the integrity of the finished product but also enables greater flexibility in design and material choices. The adoption of low pressure injection molding is anticipated to reach a compound annual growth rate (CAGR) of 5.4% through 2027, as reported by Research and Markets, highlighting its importance in the production strategies of forward-thinking enterprises. By leveraging these ten expert tips, manufacturers can streamline their operations, improve output quality, and ultimately contribute to a more sustainable production environment.

Low pressure injection molding is a cost-effective method that allows manufacturers to enhance efficiency in their production processes. To help you achieve optimal cost savings, consider implementing these techniques.

One effective technique is optimizing the mold design. A well-designed mold not only improves cycle times but also ensures uniform cooling, thus reducing energy consumption. Additionally, selecting high-quality materials can significantly lower defect rates, which in turn decreases waste and rework costs.

Another approach involves utilizing advanced control systems. By integrating sensors and automation into the production line, manufacturers can achieve better oversight of the molding process, leading to quick adjustments for minimizing downtime. This technology not only boosts production efficiency but also enables a more agile response to changing market demands, aligning with the theme of innovation and collaboration prominent in industry events like the upcoming AAC 2025 conference.

Lastly, investing in employee training can create a knowledgeable workforce adept at maximizing the potential of low pressure injection molding systems, leading to long-term efficiency gains and reduced operational costs.

| Tip Number | Technique | Expected Cost Savings (%) | Efficiency Improvement (%) | Additional Benefits |

|---|---|---|---|---|

| 1 | Optimize Molding Parameters | 10 | 15 | Increased part accuracy |

| 2 | Regular Maintenance of Equipment | 8 | 12 | Prolonged machine lifespan |

| 3 | Use of Advanced Materials | 12 | 20 | Better strength-to-weight ratio |

| 4 | Streamline Workflow Processes | 15 | 25 | Reduced production cycle time |

| 5 | Implement a Quality Control System | 10 | 18 | Fewer defects and reworks |

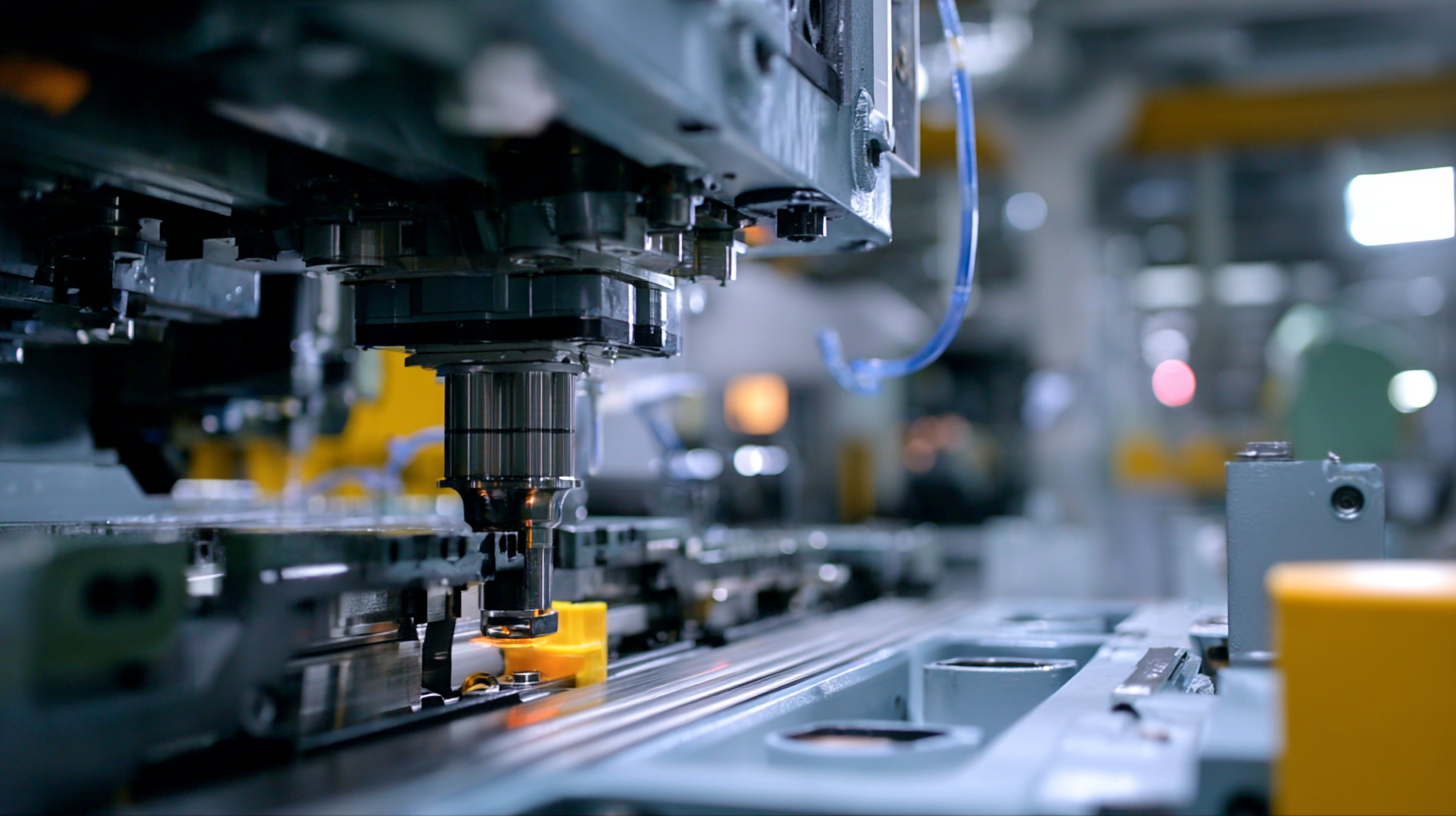

Upgrading key equipment in low pressure injection molding can significantly enhance production efficiency and reduce operational costs. One crucial upgrade is the implementation of advanced injection molding machines that feature enhanced precision controls. These machines can optimize the injection speed and pressure, allowing for better material flow and reduced cycle times. By ensuring that the right amount of material is injected at optimal conditions, manufacturers can minimize waste and improve product quality.

Another important aspect of enhancing efficiency is the incorporation of automated systems. Integrating robotics for part handling and process monitoring can streamline production workflows, reduce labor costs, and increase consistency in output. Additionally, using smart sensors and IoT technology can provide real-time data on equipment performance, facilitating timely maintenance and minimizing downtime. These upgrades not only boost the efficiency of low pressure injection molding processes but also contribute to overall cost reduction in production.

In low pressure injection molding operations, effective process monitoring is crucial for optimizing efficiency and reducing production costs. According to a report by Grand View Research, the global market for injection molding is expected to reach $408.4 billion by 2025, driven by the increasing demand for innovative materials and applications.

Implementing best practices for monitoring can significantly enhance the production process by ensuring consistent quality and minimizing waste. Key metrics such as cycle time, temperature, and pressure must be continuously tracked to identify discrepancies early in the process.

Utilizing advanced technologies such as real-time data analytics and machine learning can further refine monitoring efforts. A study by the Society of Plastics Engineers revealed that manufacturers who implemented real-time monitoring systems reduced their defect rates by up to 30%. This improvement not only boosts overall efficiency but also contributes to cost savings, which is vital in a competitive market.

Emphasizing a proactive approach to process monitoring enables manufacturers to address potential issues before they escalate, creating a more streamlined and economically advantageous production environment.

Material selection is a crucial factor in the success of low pressure injection molding, impacting both efficiency and cost-effectiveness. According to industry reports, utilizing advanced thermoplastics can reduce production cycles by up to 30%, allowing manufacturers to achieve higher output without compromising quality. Selecting the right material not only enhances the flow characteristics during the injection process but also improves the mechanical properties of the final product, which is essential for meeting stringent quality standards.

Recent innovations in multi-cavity molding techniques further illustrate the importance of strategic material selection. By optimizing material properties, manufacturers can increase their throughput and minimize waste, leading to significant cost savings. A study conducted by the International Society of Plastics Engineers revealed that optimizing materials for low pressure applications can lead to a reduction in clamping force requirements, thus reducing equipment wear and prolonging machinery life. This not only enhances overall productivity but also allows companies to allocate resources more efficiently in their production processes.

Recent innovations in multi-cavity molding techniques further illustrate the importance of strategic material selection. By optimizing material properties, manufacturers can increase their throughput and minimize waste, leading to significant cost savings. A study conducted by the International Society of Plastics Engineers revealed that optimizing materials for low pressure applications can lead to a reduction in clamping force requirements, thus reducing equipment wear and prolonging machinery life. This not only enhances overall productivity but also allows companies to allocate resources more efficiently in their production processes.

Injection molding is a vital process in manufacturing, but unplanned downtimes can significantly impact productivity and costs. According to a report by the Society of Plastics Engineers, machinery failures can lead to a staggering 30% reduction in operational efficiency in injection molding operations. To combat this, implementing innovative maintenance strategies is crucial. Regular maintenance schedules, predictive analytics, and advanced monitoring systems are pivotal in identifying potential equipment issues before they escalate into costly breakdowns.

Additionally, the introduction of condition-based maintenance systems can optimize machine usage and reduce unnecessary downtime. For instance, a study by Deloitte found that predictive maintenance could decrease maintenance costs by up to 25% while boosting machine lifespan by approximately 20%. By leveraging data analytics and IoT technologies, manufacturers can collect real-time data to monitor equipment health, which aids in making informed decisions about maintenance schedules. Empowering teams with proper training and investing in quality replacement parts also play a significant role in enhancing the reliability of injection molding processes, thus ensuring smoother operations and reduced downtime.

This chart illustrates the impact of various low-pressure injection molding tips on production efficiency and cost reduction. The data showcases the percentage improvement in efficiency and cost savings achieved through innovative maintenance practices.