The 138th Canton Fair in 2025 promises to be a pivotal platform for showcasing the latest advancements and innovations in various industries, particularly in the realm of low pressure injection technology. This cutting-edge method, known for its efficiency and effectiveness in producing high-quality molded products, is gaining traction among manufacturers looking to enhance their production capabilities while minimizing costs and environmental impact.

As industry leaders and experts gather in Guangzhou, attendees will have the unique opportunity to explore the potential of low pressure injection in revolutionizing manufacturing processes. From automotive components to consumer goods, the applications of this technology are vast and varied. The fair will not only highlight the technological breakthroughs but also foster collaboration and knowledge exchange among participants, making it a significant event for anyone interested in the future of manufacturing and innovation.

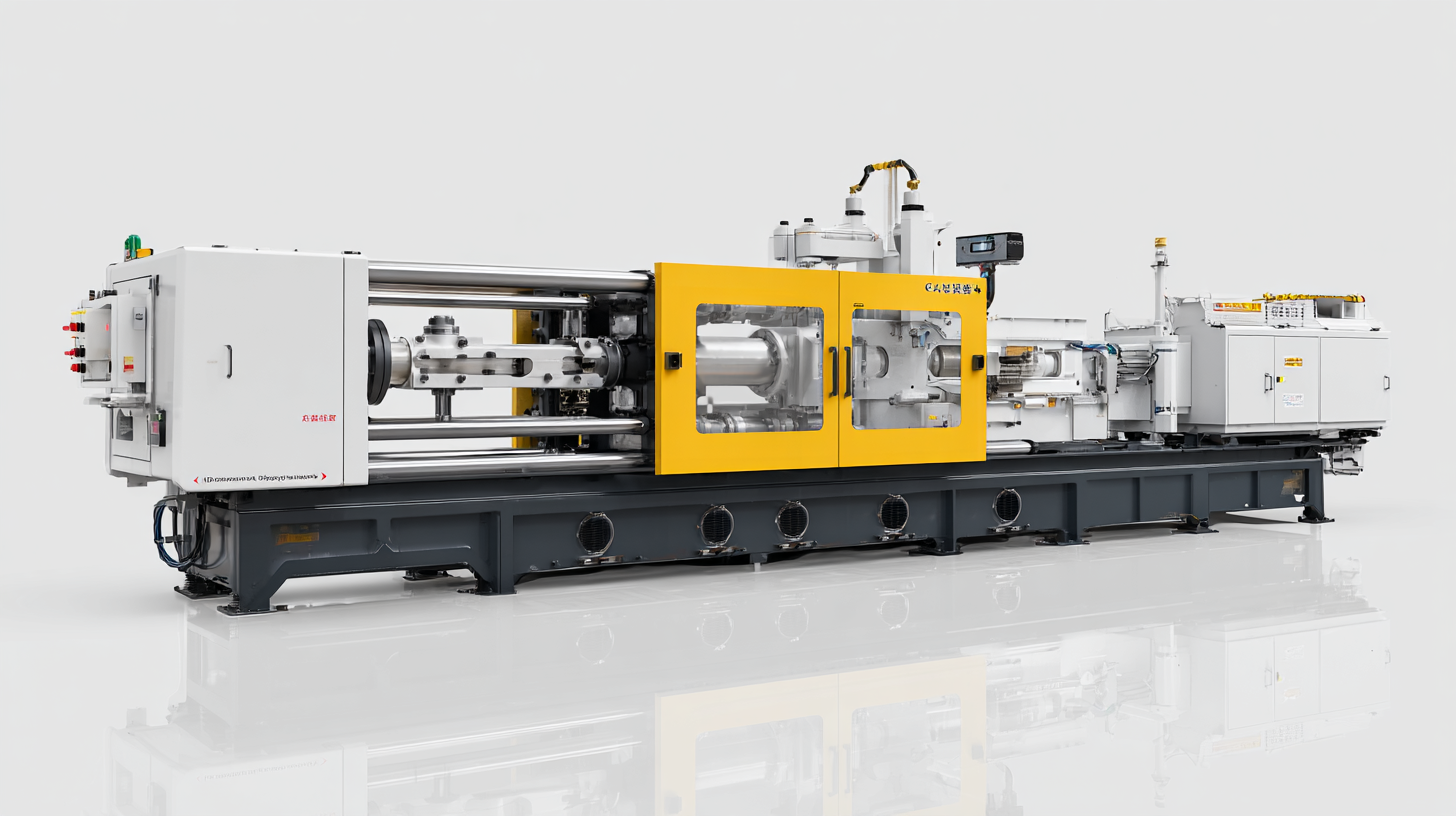

At the 138th Canton Fair in 2025, the spotlight was on innovative low pressure injection techniques that promised to revolutionize the manufacturing landscape. This year's fair featured a myriad of advancements that not only enhance efficiency but also improve product quality across various industries. Exhibitors showcased state-of-the-art systems that utilize lower pressures for injection molding, which minimizes material waste while ensuring precision in the shaping of complex components.

Among the highlights was a new method that integrates smart technology, enabling real-time monitoring and adjustments during the injection process. This approach not only maximizes productivity but also ensures a more sustainable manufacturing cycle. Additionally, breakthroughs in materials compatible with low pressure injection were introduced, expanding the potential applications of these techniques in sectors like automotive, aerospace, and consumer goods. The enthusiasm surrounding these innovations reflected a collective movement towards smarter, more eco-friendly production methods that meet modern industry demands.

The manufacturing sector has seen a significant transformation with the latest innovations in low pressure injection technology. As industries pivot towards more efficient and sustainable practices, low pressure injection stands out as a groundbreaking method that not only reduces material waste but also enhances product quality. This technique, characterized by its ability to create complex components with minimal energy consumption, is attracting attention from manufacturers across various domains, including automotive, aerospace, and consumer goods.

At the 138th Canton Fair in 2025, industry leaders are expected to showcase their latest advancements in this field. The rise of low pressure injection isn't merely a trend; it's a response to the growing demand for more eco-friendly manufacturing processes. With an emphasis on reducing carbon footprints and optimizing production cycles, businesses are increasingly investing in these technologies. Attendees will have the opportunity to explore a range of innovative applications and discuss the future implications of low pressure injection on the overall manufacturing landscape. This shift signals a promising future for companies willing to embrace evolution in their production techniques, paving the way for enhanced efficiency and sustainability.

At the 138th Canton Fair in 2025, innovations in low pressure injection technology take center stage, highlighting its transformative impact on material efficiency and waste reduction. Low pressure injection processes utilize a controlled and precise application of material, which significantly reduces the amount of excess material typically generated in traditional manufacturing methods. This innovation not only optimizes the use of raw materials but also ensures a consistent quality in the end products, leading to a more sustainable production cycle.

Moreover, this technology enables manufacturers to minimize waste by allowing for the recycling or reprocessing of unused materials. As industries face increasing pressure to reduce their environmental footprint, low pressure injection presents a viable solution that aligns with global sustainability goals. This approach not only enhances operational efficiency but also contributes positively to a circular economy, illustrating how cutting-edge technology can facilitate responsible production practices across various sectors at the fair.

| Dimension | Details | Impact on Efficiency (%) | Waste Reduction (%) |

|---|---|---|---|

| Material Type A | High Strength Polymer | 25 | 15 |

| Material Type B | Recycled Resin | 30 | 20 |

| Material Type C | Biodegradable Plastic | 20 | 10 |

| Material Type D | Foamed Material | 15 | 5 |

The 138th Canton Fair in 2025 showcased

groundbreaking advancements in low pressure injection technology, featuring several case studies that highlighted its successful implementations across various industries.

One notable example is a leading automotive manufacturer that integrated low pressure injection systems into their production process. This innovation not only reduced material waste but also significantly improved the precision of component manufacturing, resulting in enhanced vehicle performance and reduced assembly time.

One notable example is a leading automotive manufacturer that integrated low pressure injection systems into their production process. This innovation not only reduced material waste but also significantly improved the precision of component manufacturing, resulting in enhanced vehicle performance and reduced assembly time.

Another success story comes from the consumer electronics sector, where a prominent company adopted low pressure injection for the production of intricate plastic housings.

This method enabled them to produce complex shapes with thinner walls, enhancing the overall design aesthetic while maintaining product durability. The implementation led to a 20% decrease in production costs, showcasing how low pressure injection technology can provide both economic and technical advantages. These case studies not only demonstrate the versatility of low pressure injection but also inspire further exploration of its potential in other sectors.

Low pressure injection (LPI) technology is emerging as a pivotal element in the realm of sustainable manufacturing practices, as highlighted by recent research advancements. The Low-Pressure Powder Injection Moulding (LPIM) process utilizes low-viscosity feedstocks, which allows manufacturers to operate at injection pressures below 1 MPa. This not only reduces energy consumption but also minimizes waste, aligning with green manufacturing principles. As sustainability becomes a critical focus across industries, integrating LPIM can significantly enhance efficiency while maintaining product quality.

The growing market for injection molding machines, particularly in regions like India, emphasizes the increasing demand for innovative manufacturing solutions. Analysts project substantial market growth from USD 830.9 million in 2025 to USD 1,759.5 million by 2035, driven by the need for more sustainable practices. As companies adopt LPI technologies, they can expect to play a crucial role in advancing eco-friendly initiatives, ensuring compliance with future regulatory standards while promoting environmental stewardship. The interplay between low pressure injection techniques and sustainable manufacturing is set to shape the future of the industry, making it an exciting domain for exploration at events like the Canton Fair.

This chart illustrates the projected adoption rate of Low Pressure Injection technology from 2019 to 2025, highlighting its increasing importance in sustainable manufacturing practices.