Understanding injection pressure is crucial in optimizing fuel efficiency and minimizing emissions in modern combustion engines. The injection pressure refers to the pressure at which fuel is injected into the combustion chamber, a key variable that significantly influences the atomization, mixing, and combustion processes. This introductory section will explore the various metrics associated with injection pressure, such as the optimal ranges for different types of engines and the impact of deviations from these norms.

Furthermore, we will discuss how varying injection pressures directly affect fuel consumption and pollutant emissions, highlighting the delicate balance engineers must maintain to achieve maximum efficiency while meeting stringent environmental regulations. By delving into the intricacies of injection pressure, we can better understand its role in enhancing engine performance and contributing to a cleaner, more sustainable future.

Injection pressure plays a pivotal role in auto engine performance metrics, directly influencing fuel atomization, combustion efficiency, and overall engine power output. According to the Society of Automotive Engineers (SAE), optimal injection pressures can enhance fuel spray characteristics, promoting better mixing with air and ensuring more complete combustion. This leads to an increase in thermal efficiency, where engines can generate more power from the same amount of fuel consumed. Studies indicate that elevating injection pressure from 20 to 30 MPa could improve fuel efficiency by up to 8%, significantly reducing carbon emissions in the process.

When considering the impact of injection pressure, it is crucial to balance performance with emissions. The right injection settings can minimize the production of pollutants, such as NOx and particulate matter. The Environmental Protection Agency (EPA) suggests that fine-tuning injection pressure can lead to a reduction of NOx emissions by approximately 15% in diesel engines. Careful calibration not only boosts power but also contributes to meeting stringent emission standards while optimizing fuel consumption.

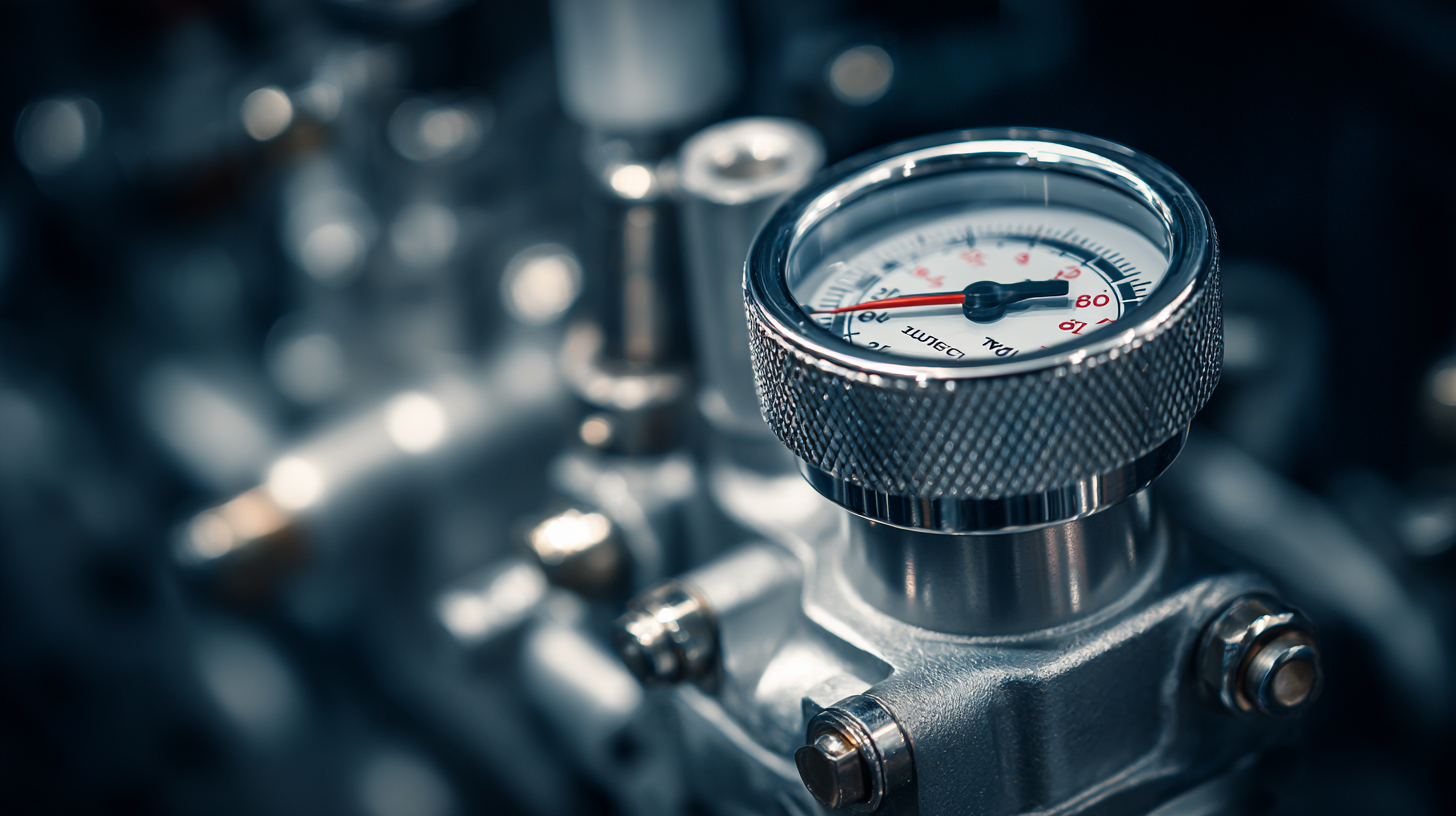

Tips: Regular maintenance of fuel injectors ensures that injection pressure remains within optimal ranges. Utilizing high-quality fuel can also prevent wear and maintain consistent performance. Lastly, monitoring engine parameters through diagnostic tools can help identify any irregularities in injection pressure early on, preventing efficiency losses.

Injection pressure plays a crucial role in determining the fuel efficiency of modern vehicles. As the pressure of fuel injected into the combustion chamber increases, the atomization of fuel improves, leading to a more thorough mix with air. This process optimizes combustion, allowing for more complete fuel utilization during engine operation. In this regard, higher injection pressures are often associated with enhanced fuel efficiency, as the engine is able to extract maximum energy from the fuel consumed.

However, the relationship between injection pressure and fuel efficiency is not a straightforward one. While elevated pressure can increase efficiency, it may also lead to higher emissions if the combustion process becomes less stable. This can occur when the fuel is injected too quickly or at an excessively high pressure, which might create a mixture that results in incomplete combustion.

Consequently, automakers continually balance these elements, conducting rigorous testing to find an optimal injection pressure that maximizes fuel efficiency while minimizing harmful emissions. Understanding this correlation is key for improving engine designs and meeting stringent environmental regulations in the automotive industry.

Injection pressure is a crucial variable influencing the combustion process in diesel engines, directly affecting both fuel efficiency and emissions. Recent studies indicate that increasing the injection pressure can enhance the atomization of fuel, promoting a more complete combustion. According to a report by the Engineering Society of Mechanical Engineers (ESME), a rise in injection pressure from 800 bar to 1200 bar can lead to a reduction in unburned hydrocarbons (HC) by up to 20% and nitrogen oxides (NOx) emissions by 15%. This is attributed to the finer fuel atomization and improved mixing with air, which allows for better combustion characteristics.

On the other hand, excessively high injection pressures can also have detrimental effects. For instance, a report from the International Council on Clean Transportation (ICCT) highlights that while higher pressures may reduce emissions initially, they can lead to increased wear and tear on engine components and higher particulate matter (PM) emissions due to incomplete combustion under certain conditions. Therefore, it is critical to find an optimal balance in injection pressure settings to achieve the desired emission targets while maintaining fuel efficiency. Fine-tuning this parameter is essential for engine manufacturers aiming to meet stringent emission regulations and improve the overall performance of diesel engines.

The comparative study of high versus low injection pressure effects on engine durability reveals critical insights into how these metrics impact overall engine performance. Higher injection pressures have been shown to enhance fuel atomization, leading to a more homogeneous air-fuel mixture. This can improve combustion efficiency and significantly reduce particulate matter emissions in gasoline direct injection (GDI) engines. For instance, studies indicate that varying injection pressures, such as 10 MPa versus 60 MPa, directly alter the macroscopic characteristics of fuel sprays, affecting combustion dynamics and, consequently, emissions profiles.

Moreover, the relationship between injection pressure and engine durability cannot be understated. Higher injection pressures may enhance performance but can also contribute to increased wear and tear on engine components due to more aggressive combustion conditions. Balancing these factors is essential for achieving optimal engine longevity while maintaining efficiency and reduced emissions. This nuanced understanding is vital as the automotive industry shifts towards more sustainable practices and fuel alternatives, including biofuels and hydrogen, that require innovative approaches to injection strategies and engine design.

Optimizing injection pressure is crucial for enhancing fuel efficiency and reducing emissions in modern fuel systems. According to the Society of Automotive Engineers (SAE), the optimal injection pressure typically ranges from 200 to 250 bar for diesel engines, which can significantly improve the atomization of the fuel, allowing for a more complete combustion process. By adhering to these industry standards, manufacturers can ensure that their engines operate on the most efficient combustion cycle, minimizing unburnt fuel and harmful emissions.

Implementing best practices for managing injection pressure also involves regular calibration and maintenance of fuel injectors. A report by the International Council on Clean Transportation (ICCT) emphasizes the importance of maintaining the correct injection pressure settings, as deviations can lead to a loss of fuel economy by up to 15%. Furthermore, advances in technologies such as variable injection pressure systems are being adopted, providing greater control over fuel delivery and further optimizing engine performance. By following these industry standards and utilizing innovative technologies, operators can significantly contribute to environmental sustainability while maximizing operational efficiency.