In today’s rapidly evolving manufacturing landscape, the integration of advanced technologies is essential for enhancing efficiency and productivity. Injection molding products have emerged as a game-changer in this domain, significantly transforming production processes. According to a report by Grand View Research, the global injection molding market size is projected to reach USD 405.02 billion by 2027, growing at a CAGR of 5.2%. This impressive growth underscores the vital role of injection molding in meeting the demands for high-quality, precision-engineered components across various industries. By leveraging cutting-edge techniques and materials, manufacturers are now able to streamline operations, reduce waste, and improve product quality. This article will explore five key ways injection molding products are revolutionizing manufacturing efficiency, providing insights that highlight their impact on both operational performance and competitive advantage in the market.

Injection molding has become a pivotal process in manufacturing, particularly in maximizing material utilization. According to a report by the Plastics Industry Association, efficient use of materials can lead to a reduction in waste by up to 30%, significantly cutting production costs and environmental impact. Advanced injection molding techniques, such as multi-material molding and in-mold labeling, allow manufacturers to produce complex components with minimal scrap, ensuring that every ounce of material is effectively used.

Moreover, implementing specific strategies such as optimizing cycle times and utilizing simulation software can enhance the precision of material flow during the injection process. A study published in the journal "Polymer Engineering and Science" revealed that manufacturers leveraging these advanced techniques can achieve up to 25% greater yield from raw materials. This not only speeds up production but also leads to better cost efficiency and sustainability, ultimately transforming the manufacturing landscape while meeting the increasing demand for high-quality, low-defect products.

| Method | Benefit | Material Utilization (%) | Cycle Time (seconds) | Cost Reduction (%) |

|---|---|---|---|---|

| Optimized Injection Pressure | Improved surface finish and precision | 95% | 30 | 15% |

| Advanced Mold Design | Greater mold longevity | 92% | 28 | 10% |

| Material Recycling Techniques | Sustainability and cost-effectiveness | 90% | 32 | 20% |

| Real-Time Monitoring Systems | Immediate error detection | 93% | 25 | 18% |

| Incorporation of Smart Technologies | Enhanced automation and efficiency | 94% | 26 | 22% |

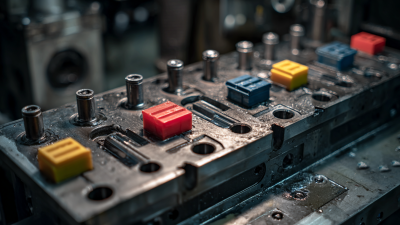

Automated injection molding systems have revolutionized the manufacturing landscape by significantly enhancing production speed and efficiency. These advanced systems streamline the entire molding process, allowing for rapid material handling and precision in component production. For instance, recent developments in smart manufacturing facilities have highlighted how automated techniques can reduce cycle times to mere seconds, optimizing the workflow and minimizing downtime. The capability to produce intricate components, such as those required for consumer electronics or automotive applications, has vastly improved, underscoring the versatility of automated injection molding.

Moreover, the increasing demand for high-volume production aligns perfectly with the advancements in injection molding technology. Companies are now investing in fully automated lines that not only decrease labor costs but also foster consistent quality in outputs. As exemplified by projects dedicated to producing humanoid robots or sophisticated electronic devices, automation in injection molding is creating more agile production environments. This transformation is pivotal for manufacturers aiming to meet market needs while maintaining competitive advantages in an ever-evolving industry.

The integration of smart technology in injection molding is revolutionizing the way manufacturers monitor and manage their production processes. Real-time process monitoring allows manufacturers to collect data from various stages of molding, enabling them to track performance and identify potential issues before they escalate. This immediate feedback loop ensures that adjustments can be made on the fly, significantly reducing downtime and improving overall production efficiency.

Moreover, smart technology facilitates predictive maintenance by analyzing patterns and trends in machine performance. With advanced analytics, manufacturers can preemptively address machinery wear and optimize maintenance schedules, leading to enhanced durability and reduced operational costs. The ability to remotely monitor equipment through IoT devices further streamlines the oversight process, allowing for quicker responses to anomalies and ensuring high-quality outputs throughout the production lifecycle.

Injection molding has become a cornerstone of modern manufacturing, particularly as it relates to reducing waste and minimizing energy consumption. By leveraging advanced technologies and materials, manufacturers can create high-quality products while adhering to eco-friendly practices. For instance, techniques like reusing scrap material significantly contribute to lowering raw material costs and diminishing landfill waste. This not only enhances the sustainability of production processes but also promotes a circular economy where resources are effectively utilized.

Additionally, energy-efficient molding machines play a crucial role in transforming manufacturing operations. These machines are designed to consume less energy during production, which directly influences the overall carbon footprint of manufacturing activities. Integrating smart technology in injection molding processes allows real-time monitoring and optimization, ensuring that energy use is minimized without compromising on productivity. As manufacturers increasingly adopt these eco-friendly practices, they not only fulfill their corporate social responsibilities but also benefit from improved operational efficiency and reduced costs.

Precision injection molding is a game-changer in the manufacturing sector, significantly improving product quality and consistency. According to a report by the Society of Plastics Engineers, the adoption of precision injection molding processes has been shown to enhance dimensional accuracy by up to 50% compared to traditional methods. This level of precision minimizes variation and defects, thereby increasing output quality and reducing waste — a critical factor given that manufacturing waste costs industries approximately $100 billion annually.

Moreover, precision in injection molding also directly contributes to consistency across production runs. A study from the American Society of Mechanical Engineers highlights that manufacturers using advanced injection molding techniques report a 30% decrease in part-to-part variation, which bolsters overall operational efficiency. With the ability to produce complex geometries consistently, businesses are not only meeting but exceeding customer expectations, ensuring that their products maintain high standards and fostering brand loyalty in competitive markets.