The manufacturing industry constantly seeks ways to improve production efficiency, and innovative techniques in injection molding mold design are at the forefront of this evolution. According to a report by Market Research Future, the global injection molding market is projected to reach USD 258.57 billion by 2025, driven by rising demand for lightweight and complex geometrical shapes in various sectors, including automotive and consumer goods. This growth emphasizes the need for advanced mold design strategies that not only enhance the production process but also reduce lead times and production costs. By adopting cutting-edge technologies such as simulation software and additive manufacturing in injection molding mold creation, manufacturers can achieve higher precision and quicker turnaround times. As a result, businesses that leverage these innovative techniques stand to gain a competitive edge in a rapidly evolving market, making it imperative for industry players to explore and implement best practices in injection molding mold design for enhanced operational efficiency.

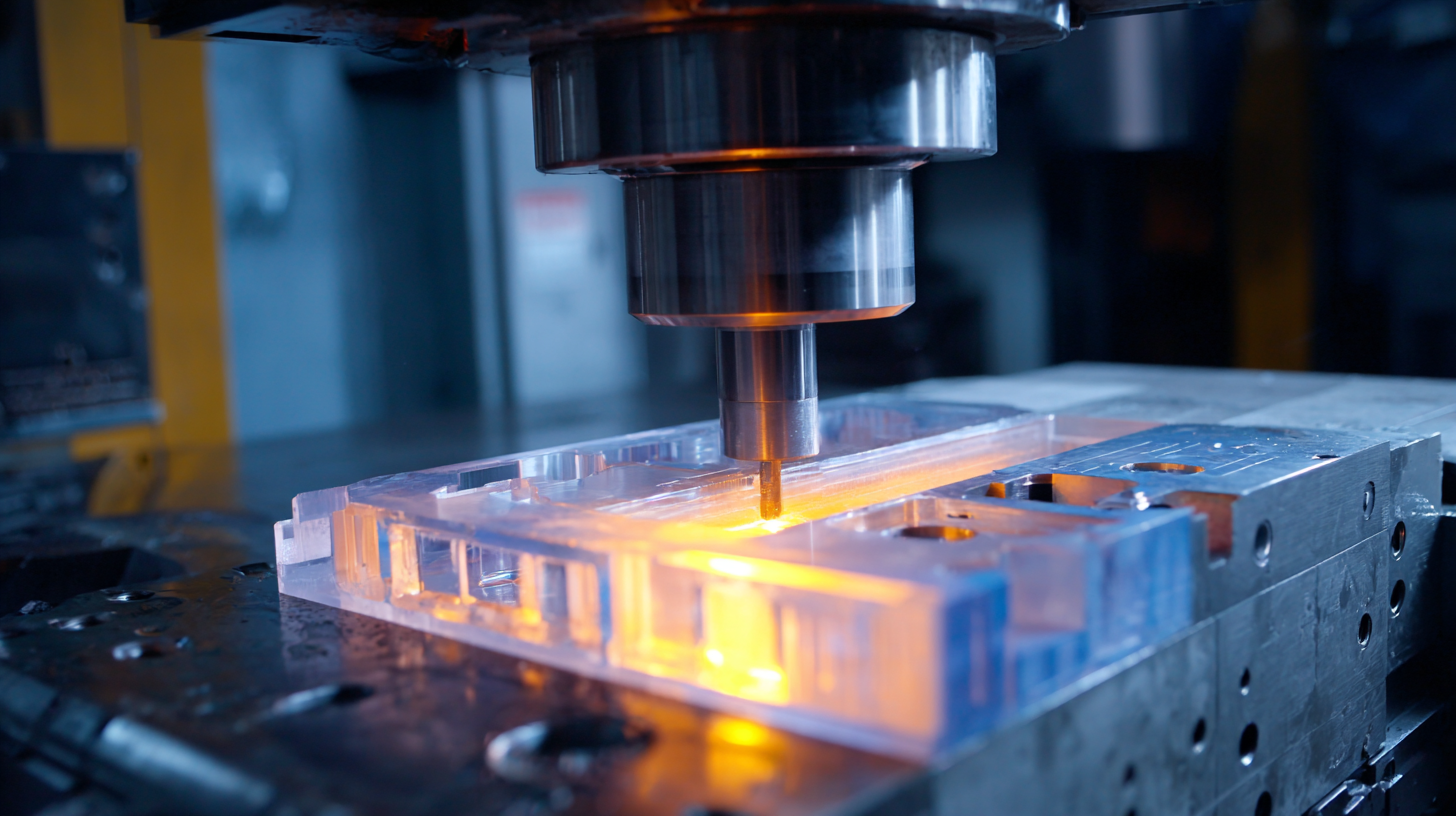

In the realm of injection molding, the evolution of mold design has become crucial for enhancing production efficiency. Innovative strategies are being implemented to streamline the design process, allowing manufacturers to maximize their output while minimizing waste. One effective approach is the integration of computer-aided design (CAD) software with simulation tools, enabling designers to visualize and test their molds in a virtual environment. This not only reduces the time taken to identify potential issues but also facilitates more precise designs that can optimize material flow and cooling processes.

Another significant development is the adoption of modular mold systems. By utilizing interchangeable components, manufacturers can quickly adapt their molds for different products without the need for extensive retooling. This flexibility not only speeds up production times but also allows for cost savings, as fewer unique molds need to be produced and maintained. Furthermore, incorporating additive manufacturing techniques into mold design can enhance the creation of complex geometries that were previously difficult to achieve, thus pushing the boundaries of what is possible in injection molding. Together, these innovative strategies contribute to a more agile and efficient molding process, capable of meeting the demands of rapidly changing market conditions.

This chart illustrates the impact of various innovative techniques in mold design on production efficiency within the injection molding process over a specific time period.

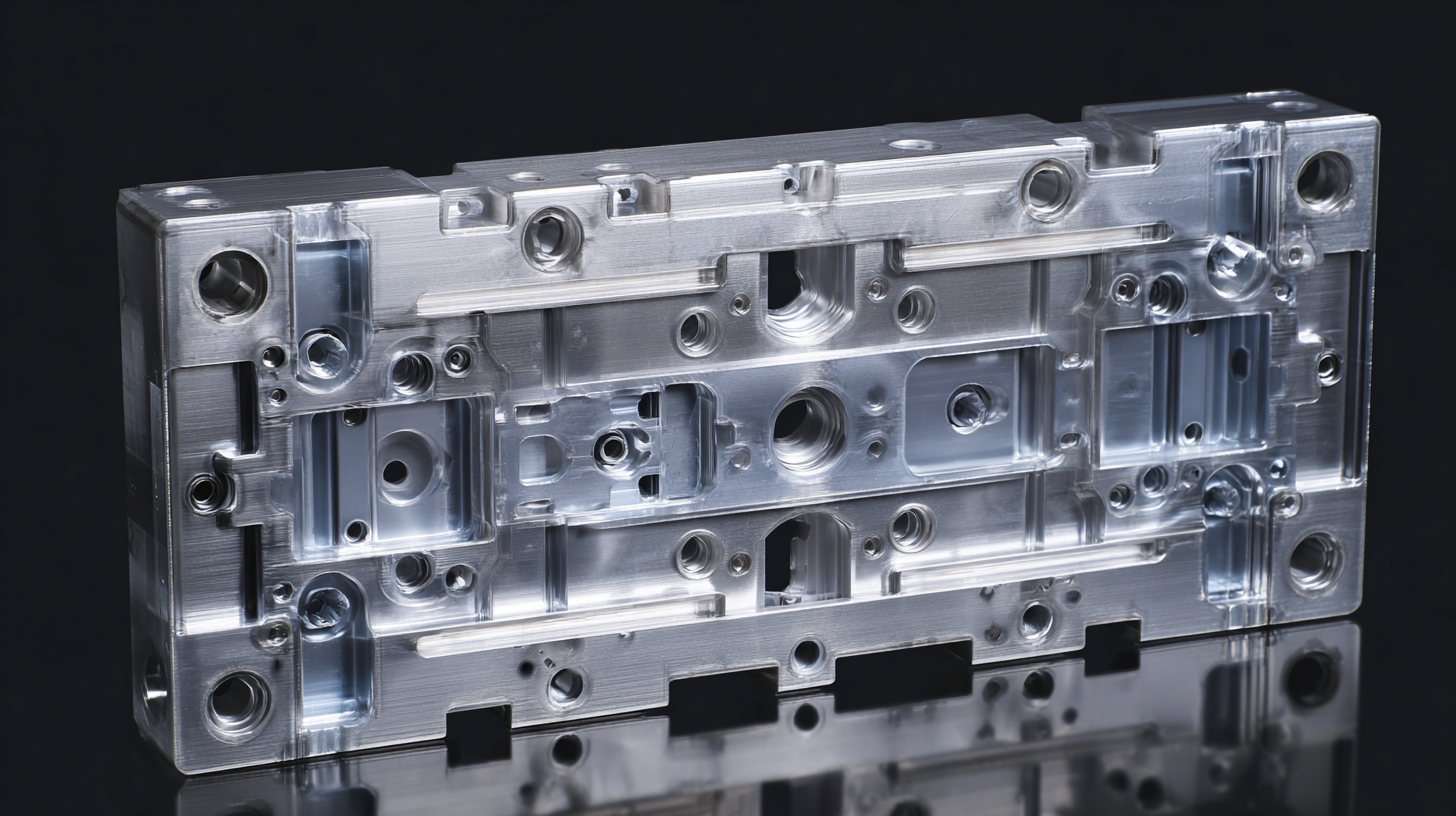

In the realm of modern injection molding, utilizing advanced materials for mold durability and performance is paramount for driving production efficiency. Recent reports from the Society of Plastics Engineers indicate that the incorporation of high-performance materials like P20 steel and aluminum alloys can significantly extend mold life by up to 50%. These materials not only withstand higher thermal and mechanical stresses but also minimize cycle times, allowing for quicker production rates without sacrificing quality.

One effective technique in mold design is the use of conformal cooling channels, which optimize temperature distribution within the mold. According to a study by the American Society of Mechanical Engineers, molds designed with conformal cooling can improve cooling efficiency by 30%, consequently decreasing cycle times. This advancement facilitates better surface finishes and dimensional accuracy in the final products.

Tips: When selecting materials for mold design, consider the specific requirements of your production process, including thermal properties and wear resistance. Regular maintenance and monitoring of molds can also prolong their lifespan and maintain optimal performance. Embrace technologies like 3D printing to prototype and iterate mold designs rapidly, allowing for efficient testing and adjustments before full-scale production.

The integration of smart technology in injection molding mold design significantly enhances production efficiency by enabling real-time monitoring and adjustments. Implementing advanced sensors and Internet of Things (IoT) devices allows manufacturers to gather data continuously throughout the molding process. This data facilitates immediate decision-making, minimizing waste and reducing processing times. By employing artificial intelligence algorithms, insights derived from real-time data can lead to automated adjustments in temperature, pressure, and cycle times, optimizing the entire production line dynamically.

Moreover, the utilization of digital twin technology in conjunction with smart molds creates a virtual representation of physical processes. This integration allows engineers to simulate various scenarios and predict outcomes before actual production, further refining the process. As AI and IoT technologies evolve, their application in injection molding promises to not only enhance production efficiency but also contribute to sustainability by reducing energy consumption and material waste during manufacturing. The synergy between smart technology and traditional mold design is paving the way for a more efficient and environmentally responsible future in the manufacturing sector.

The injection molding industry is increasingly adopting eco-friendly practices in mold design to foster sustainability and reduce environmental impact. One of the innovative techniques involves using biodegradable materials in the creation of molds, which not only minimizes waste but also ensures that products can decompose naturally after their useful life. Additionally, incorporating recycled materials in the manufacturing process aids in reducing the carbon footprint associated with traditional mold design.

Another key aspect is the implementation of energy-efficient technologies in the operations of injection molding. By optimizing the cooling and heating processes, manufacturers can significantly cut down energy consumption. Using advanced simulation software during the design phase allows engineers to predict and mitigate potential inefficiencies, focused on reducing cycle times and material usage. These steps not only enhance production efficiency but also align with a growing emphasis on sustainability, demonstrating that eco-friendly practices and excellent production performance can coexist harmoniously in modern mold design.

| Technique | Description | Benefits | Sustainability Aspect |

|---|---|---|---|

| Computer-Aided Design (CAD) | Utilization of advanced software to create precise mold designs. | Increases accuracy, reduces material waste. | Minimizes resource usage and improves recyclability. |

| 3D Printing for Mold Prototyping | Creating mold prototypes quickly and efficiently using 3D printers. | Speeds up the design process and allows for rapid testing. | Reduces time and energy in traditional manufacturing processes. |

| Simulation Software | Running simulations to predict manufacturing outcomes and optimize designs. | Improves efficiency and quality of final products. | Enables better resource management and waste reduction. |

| Use of Biodegradable Materials | Incorporating biodegradable plastics into the injection molding process. | Contributes to environmental conservation and reduces landfill waste. | Promotes sustainability in material selection. |

| Energy-Efficient Machines | Utilizing machines designed to consume less power. | Reduces operational costs and environmental footprint. | Encourages energy conservation practices in manufacturing. |

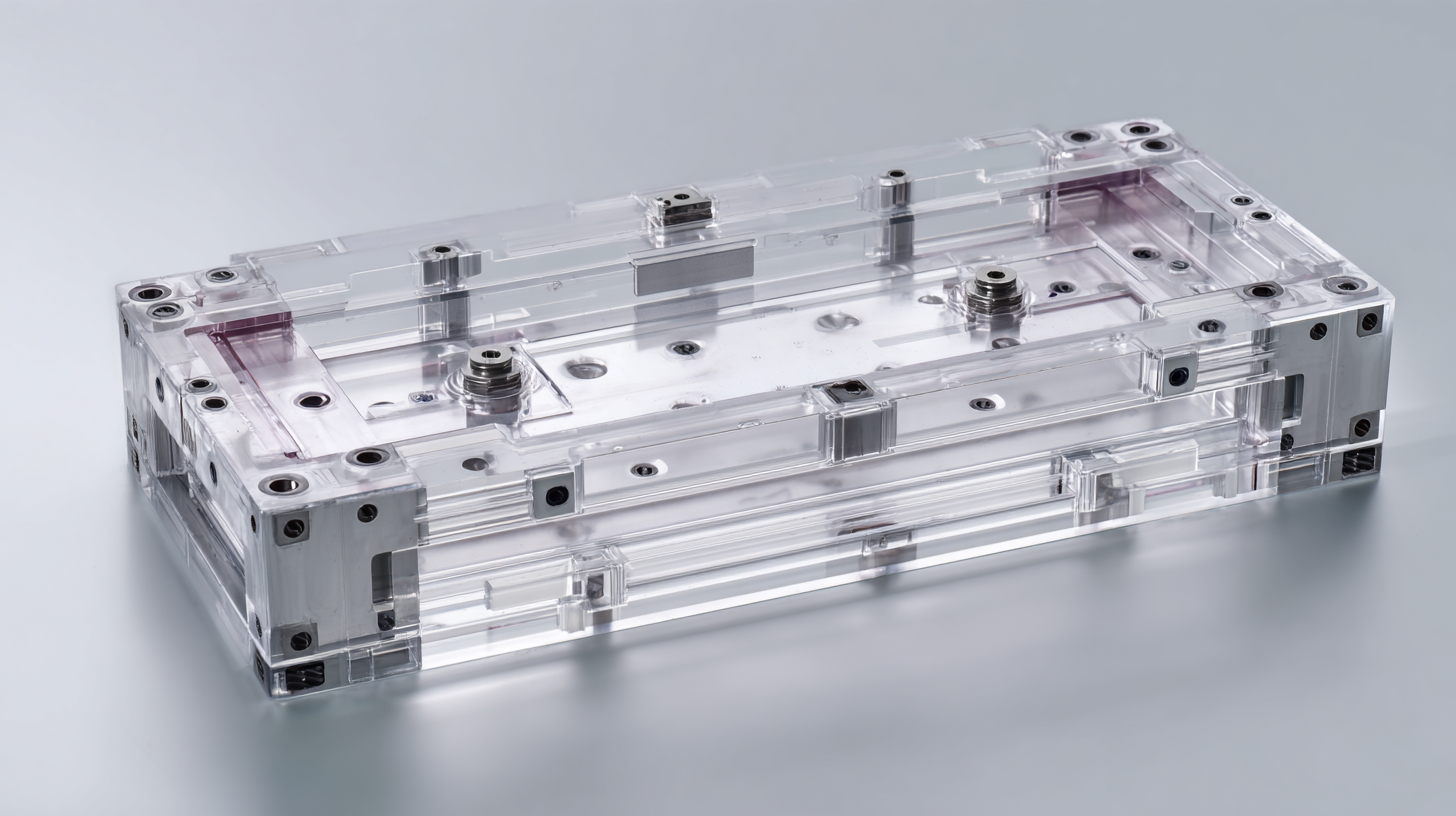

The implementation of modular and flexible mold systems has revolutionized production cycles in injection molding. By allowing manufacturers to interchange specific components of molds, these systems significantly reduce downtime and enhance adaptability to changing product designs. This flexibility empowers companies to respond more swiftly to market demands, enabling them to produce varying products without the need for completely new molds. Consequently, this not only streamlines production processes but also minimizes costs associated with mold maintenance and re-tooling.

Moreover, the modular approach facilitates improved maintenance practices. Components can be easily accessed and replaced without affecting the overall efficiency of the production process. This not only leads to decreased lead times but also enhances the quality of the molded products, as the molds can be optimized individually and assembled to suit specific production needs. Overall, utilizing modular and flexible mold systems is a key strategy for manufacturers aiming to achieve higher efficiency and maintain competitiveness in the fast-paced injection molding industry.