In recent years, the injection machine has emerged as a pivotal technology in modern manufacturing. These machines have transformed production lines, offering speed and precision. The rise of automation has further enhanced their efficiency. As industries demand higher quality at lower costs, injection machines deliver just that.

Nonetheless, challenges persist in the adoption of these technologies. Companies must balance investment with the need for skilled operators. Training staff requires time and resources, which can be a hurdle. Additionally, maintaining older machines while integrating new models presents a significant learning curve.

Despite these obstacles, the benefits of injection machine innovations cannot be ignored. They increase throughput and improve product quality. Embracing these advancements is essential for staying competitive in today’s fast-paced market. As manufacturers evaluate new technologies, the future of injection machines looks promising yet complex.

The rise of advanced injection machine technologies is transforming the manufacturing landscape. These innovations improve efficiency and sustainability. They enable faster production times and reduce waste. Companies can now create more complex shapes and designs with precision. This versatility allows manufacturers to meet diverse customer needs.

However, challenges persist. Adoption of new technologies can be slow. Workers may need retraining to use advanced machines effectively. There's also the risk of over-reliance on technology, which may hinder creativity. Continuous evaluation of processes is essential for improvement.

Tip: Regularly assess your production methods to identify potential areas for advancement. This can lead to better efficiency and lower costs. Embrace change but remain mindful of its impact on creativity and workforce dynamics.

Investing in technology is crucial, yet it’s equally important to foster a culture of innovation among employees. Encourage teams to share ideas and learn from each other. This collaboration can drive further advancement in manufacturing processes.

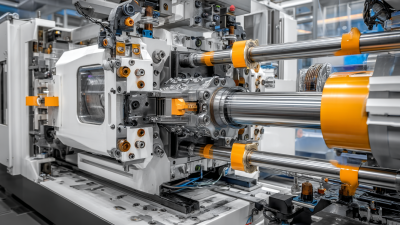

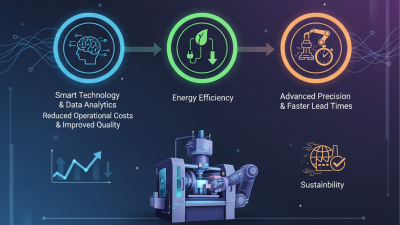

The landscape of manufacturing is changing rapidly, thanks to innovations in injection molding machinery. Advanced technologies like electric injection molding machines have entered the spotlight. They offer high precision and energy efficiency, significantly reducing operational costs. These machines can produce complex parts with great accuracy, which is critical in today’s competitive market.

Another interesting development is the use of smart sensors. These sensors monitor production in real-time, detecting faults immediately. This capability enhances quality control, but it also raises questions about reliance on technology. What happens when systems fail? It’s a critical concern that manufacturers must address. The integration of automation is a double-edged sword; it improves efficiency but creates a need for ongoing maintenance and training.

Lastly, advancements in materials are also noteworthy. Bio-based and recycled materials are gaining traction in injection molding. They not only meet environmental standards but also offer unique properties. However, the transition is not seamless. Manufacturers often face challenges with material compatibility and processing conditions. These hurdles require careful planning and adaptation, reminding us that innovation doesn’t come without its difficulties.

Automation in injection molding machines significantly enhances efficiency. This technology reduces human error and streamlines repetitive tasks. With precision and speed, manufacturers can produce complex parts faster than before. Automation allows continuous operation, increasing output while minimizing labor costs.

However, relying solely on automation can pose challenges. Machines can malfunction, leading to costly downtime. Skilled workers are still essential for maintenance and oversight. Training employees to work alongside automated systems is crucial for optimal productivity. While automation boosts capabilities, it’s important to reflect on the balance between technology and human expertise.

Adopting this technology requires careful planning. Integration must consider workflow and existing setups. Companies need to evaluate their specific needs. The goal is to enhance production without disrupting current processes. Finding this balance is an ongoing quest for many manufacturers.

The evolution in injection molding is addressing sustainability in remarkable ways. Modern techniques now incorporate recycled materials into their processes. This not only reduces waste but lowers production costs. Manufacturers are now focusing on energy-efficient machines that consume less power during operation. This shift is essential for decreasing carbon footprints.

Consider these tips for sustainable injection molding:

Despite advancements, challenges persist. Many manufacturers still use conventional methods that aren't eco-friendly. They hesitate to change existing processes, fearing disruptions. However, embracing new technologies can lead to a more sustainable future. It’s important to reflect on past practices. Are we doing enough to protect the environment while manufacturing products? Keep pushing for innovation and sustainability.

The integration of smart injection machines is transforming manufacturing. These machines collect data in real-time. They adapt processes based on feedback, making production more efficient. For instance, sensors monitor temperature and pressure. If something goes wrong, the machine can adjust instantly. This minimizes defects and waste.

Industry 4.0 connection plays a crucial role here. Smart machines communicate with each other. They form a network that enhances automation. Workers can monitor everything from their devices. This shift is exciting but also daunting. The need for skilled workers to manage these technologies grows. Training programs must evolve to prepare teams for these advancements.

While progress is promising, challenges remain. There are risks of over-reliance on machines. What if the system fails? Manufacturers must maintain a balance between technology and human oversight. It’s vital to ensure that machines support, rather than replace, human skills. A cautious approach is necessary as we embrace this smart future.

| Technology | Key Features | Benefits | Integration with Industry 4.0 |

|---|---|---|---|

| Electric Injection Machines | Precision control, energy efficiency | Lower operating costs, better quality | IoT connectivity for performance monitoring |

| Hybrid Injection Machines | Combination of hydraulic and electric | Flexibility, high speed production | Seamless data integration with smart factories |

| IOT-enabled Injection Machines | Remote monitoring, predictive maintenance | Reduced downtime, enhanced productivity | Real-time data analysis and optimization |

| 3D Printing Injection Machines | Additive manufacturing capabilities | Design flexibility, rapid prototyping | Integration with CAD and AI design tools |

| Smart Sensors in Injection Machines | Real-time monitoring and feedback | Improved process control and quality assurance | Enhanced data collection for analysis |