The evolution of industrial molding techniques has been a pivotal aspect of the manufacturing landscape, shaping the way products are designed and produced. From the early days of simple molds to the advanced technologies employed today, industrial molding has undergone significant transformations that reflect advancements in materials and processing methods. This journey not only enhances the efficiency and precision of manufacturing but also influences the sustainability and scalability of various industries. By examining the progression of these techniques, we can better appreciate their profound impact on production capabilities, cost-effectiveness, and product innovation. This exploration sheds light on how different molding methods, including injection, blow, and rotational molding, have adapted to meet the growing demands for quality and performance in today's competitive markets. Understanding these changes is crucial for manufacturers aiming to leverage industrial molding in their processes and stay ahead in an ever-evolving industrial environment.

The evolution of industrial molding techniques is a pivotal aspect of manufacturing history, significantly influencing production efficiency and product quality. Early methods, such as sand casting, date back to ancient civilizations, where artisans shaped metal by pouring liquid into molds made from sand. This technique laid the groundwork for more advanced processes. According to a recent report by the American Foundry Society, over 70% of metal parts in modern manufacturing still rely on casting methods, showcasing their enduring relevance.

The introduction of plastics in the 20th century marked a transformative period in molding techniques. The advent of injection molding revolutionized the industry by allowing for intricate designs and high-volume production with minimal waste. As highlighted in a 2022 report by MarketsandMarkets, the global injection molding market is projected to reach USD 351.9 billion by 2026, demonstrating a CAGR of 5.8% from 2021. This growth signifies not only the efficiency of these techniques but also their versatility across various sectors, from automotive to consumer products, underscoring the critical role molding plays in contemporary manufacturing landscapes.

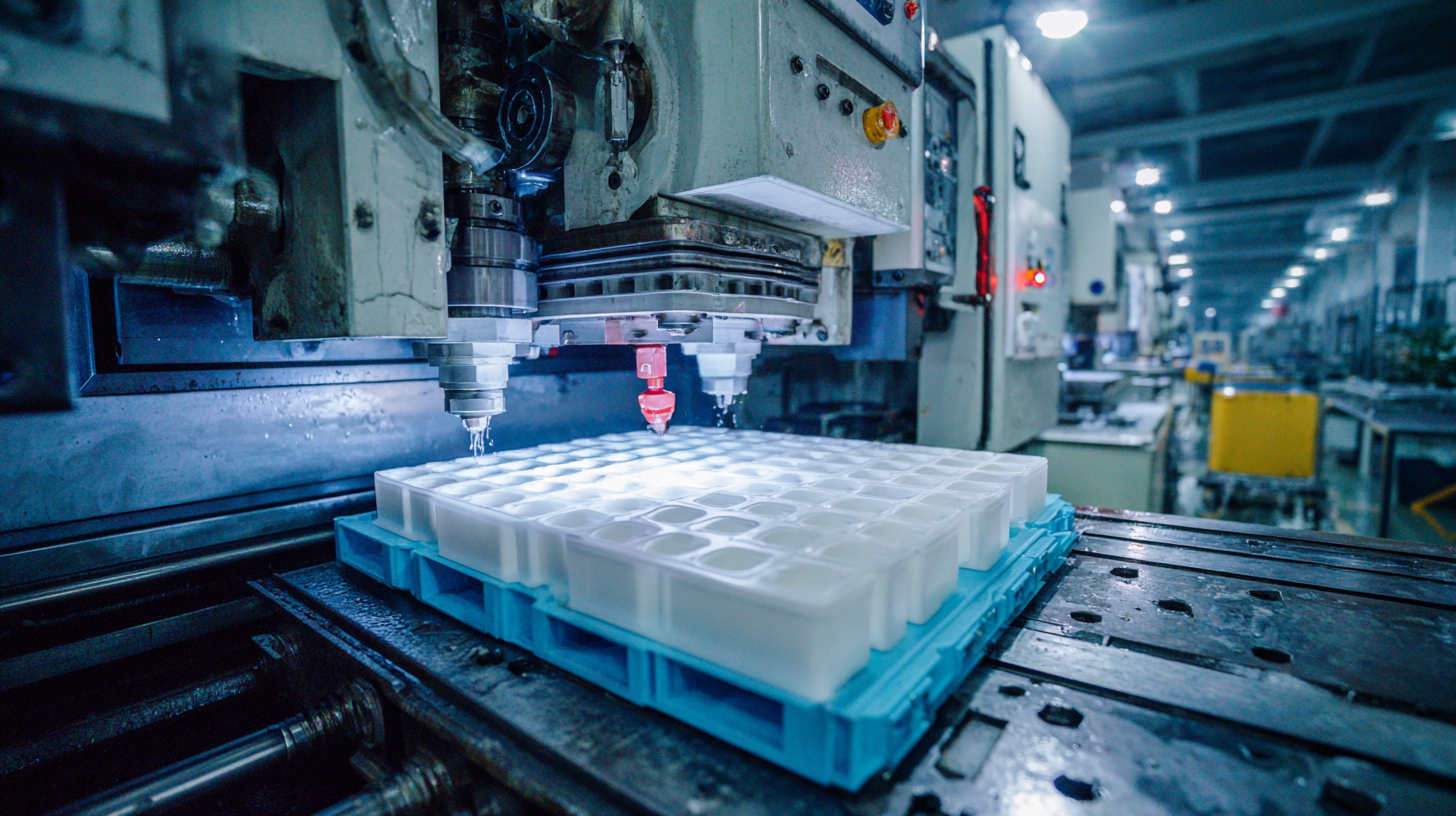

The transition from traditional to modern molding methods in manufacturing has significantly reshaped the industry landscape. Traditional molding techniques, such as sand casting and injection molding, relied heavily on manual labor and time-consuming processes. These methods often resulted in longer production cycles and higher variability in product quality. Craftsmen would meticulously shape and prepare molds, with the outcomes largely dependent on their skill and experience. Although effective in their time, these traditional approaches struggled to keep pace with the growing demand for precision and efficiency in the manufacturing sector.

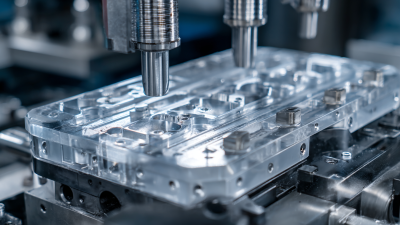

In contrast, modern molding techniques incorporate advanced technologies, such as computer-aided design (CAD) and additive manufacturing. These innovations have enabled manufacturers to produce complex geometries with improved accuracy and faster turnaround times. Automation and robotics have further streamlined operations, reducing human error and increasing production capacity. This shift not only enhances the quality of the final products but also allows for greater customization and innovation in design. As a result, industries can respond more agilely to market demands, ultimately leading to more sustainable practices and a competitive edge in the global market.

| Molding Technique | Era of Use | Materials Used | Advantages | Disadvantages | Applications |

|---|---|---|---|---|---|

| Sand Molding | Ancient to Present | Silica Sand, Clay | Cost-effective, Easy to Use | Low dimensional accuracy | Casting of Metals |

| Die Casting | 20th Century Onward | Aluminum, Zinc | High precision, Good surface finish | High initial cost | Automotive Parts, Electronics |

| Injection Molding | Mid 20th Century Onward | Plastics, Thermoplastics | High production rates, Complex shapes | Material waste, Equipment cost | Consumer Goods, Toys |

| 3D Printing | 21st Century Onward | Plastics, Metals, Ceramics | Customization, Complexity | Slow production speed | Prototyping, Medical Applications |

The evolution of industrial molding techniques has been significantly influenced by advancements in technology, particularly in the realm of additive manufacturing and smart manufacturing. According to a recent comprehensive review, the integration of lightweight composite structures and innovative manufacturing technologies is transforming the industry, providing manufacturers with greater efficiency and flexibility in production processes. For instance, additive manufacturing, which was initially viewed primarily for prototyping, is now being recognized as a long-term game changer for mass production. Research indicates that companies that adopt these technologies can drastically reduce time-to-market and improve product quality by leveraging generative design and AI-driven analytics.

Moreover, the role of engineers in optimizing molding processes cannot be overstated. They are crucial in testing methodologies, material science, and the implementation of AI tools to enhance precision in molding operations. A pivotal study highlighted how advanced technologies, including binder jetting and smart manufacturing systems, are streamlining processes and reducing waste. With these innovations, engineers play a vital role in shaping sustainable manufacturing practices, ensuring that industries not only meet product demands but also adhere to environmental standards.

The future of industrial molding is increasingly intertwined with technology, driving the industry toward a more efficient and sustainable paradigm.

The evolution of industrial molding techniques has profound environmental and economic implications, particularly with the rise of sustainable building materials and practices. Recent advancements emphasize the classification and innovative production technologies of these materials, promoting a shift towards eco-friendly alternatives. In the construction industry, for example, innovations such as mycocrete, developed from fungi, showcase how materials can not only enhance structural performance but also mitigate environmental impacts.

Tips: When considering sustainable practices, explore biodegradable materials and closed-loop recycling technologies, which minimize waste and resource loss. Additionally, investing in energy-efficient construction methods can significantly lower greenhouse gas emissions, reinforcing a commitment to environmental stewardship.

As industries embrace additive manufacturing, the potential for economic advantages becomes clear. This technology can optimize resource utilization and reduce production costs, proving to be an eco-conscious alternative to traditional methods. Continuous exploration of these evolving molding techniques not only addresses pressing environmental challenges but also paves the way for a more sustainable and economically viable manufacturing future.

The future of industrial molding techniques is poised for significant transformation, driven by advancements in technology and shifts in manufacturing demands. One notable trend is the increasing adoption of additive manufacturing, or 3D printing, which allows for greater design flexibility and reduced material waste. This technique enables manufacturers to create complex shapes and structures that were previously impossible with traditional molding methods. As materials science continues to evolve, new, high-performance polymers and composites will enable even more innovative and efficient production processes.

Additionally, automation and smart manufacturing will play crucial roles in shaping the future of industrial molding. The integration of artificial intelligence and machine learning into molding operations will enhance precision, reduce cycle times, and improve the overall efficiency of the production line. Predictive maintenance powered by IoT sensors will minimize downtime and optimize resource utilization. As these technologies converge, the industrial molding landscape will see a shift towards more agile and responsive manufacturing practices, capable of meeting the demands of a rapidly changing market while maintaining high quality standards.