Choosing the right industrial molding techniques can significantly impact product quality and manufacturing efficiency. According to Dr. Emily Carter, an expert in the industrial molding sector, “Selecting the appropriate method can make or break the production process.” Her words highlight the importance of careful consideration in this field.

Industrial molding offers various techniques, including injection molding, blow molding, and rotational molding. Each method has distinct advantages and drawbacks. For example, injection molding is efficient for high-volume production but may require expensive initial tooling. On the other hand, blow molding is ideal for hollow objects but might struggle with intricate designs.

It’s essential to weigh these factors before making a decision. An unfit choice can lead to increased costs and longer lead times. Molding isn't just about machines; it’s about understanding materials and adapting processes. Reflecting on these points can guide businesses to optimize their production and avoid common pitfalls.

Industrial molding techniques play a vital role in manufacturing. They help shape materials into desired forms. Techniques like injection molding, blow molding, and rotational molding are crucial for various industries. Reports suggest that the global molding market is expected to reach $60 billion by 2025. This growth reflects the importance of efficient molding processes.

Tips: Assess your product needs carefully. Choose a technique that aligns with material type and volume requirements. Keep in mind the costs involved. In some cases, a cheaper option might lead to higher long-term expenses due to inefficiency.

Different molding techniques serve unique functions. Injection molding is excellent for high precision, while blow molding suits hollow shapes. Notably, 30% of manufacturers report challenges in material waste during these processes. Finding ways to minimize waste can improve sustainability and reduce costs.

Tips: Analyze past projects for insights. Evaluate what worked and what didn’t. Continuous improvement is key. Consider investing in training to keep up with industry advancements. This approach can help your business stay competitive in a rapidly evolving market.

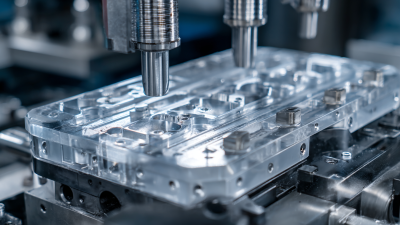

Choosing the right industrial molding technique is crucial. Several key factors play a significant role in this decision. The type of material you are using can greatly influence your choice. For instance, softer plastics may perform well with injection molding, while tougher materials might require alternative methods. Understanding the properties of the material is essential.

Production volume is another crucial factor. High-volume production often benefits from methods like blow molding. However, if you're producing in smaller quantities, a different approach, such as rotational molding, may be more effective. You must weigh the costs against expected output.

Cost is also significant. Some techniques demand high initial investment, which can be daunting. While certain methods may save money in the long run, the upfront costs can be a barrier. Additionally, the required lead time varies by technique. Some may offer faster deployment but compromise quality. Be prepared to reevaluate your approach based on these factors. Choosing a mold method is not just about efficiency; it requires balancing various elements for the best outcome.

When selecting industrial molding techniques, it's vital to evaluate their pros and cons.

Injection molding is a popular choice, known for its ability to produce complex shapes with precision. According to a 2022 industry report, this technique achieves production rates up to 10,000 parts per hour.

However, mold creation can be costly, often reaching thousands of dollars. This initial investment can deter startups.

Another option is blow molding, mainly used for hollow objects. It is cost-effective for large runs but has limitations in the complexity of shapes it can create.

A 2021 study found that blow molding's production efficiency can decrease with more intricate designs. This creates a potential mismatch between product requirements and manufacturing capabilities.

Rotational molding offers advantages for large parts and low runs, but the process can be slower and less efficient in mass production. According to recent data, it takes longer to heat and cool molds, leading to increased cycle times.

These factors can impact overall project timelines and budget constraints. Evaluating these details can help determine the best approach for specific project needs. Always weigh the trade-offs carefully.

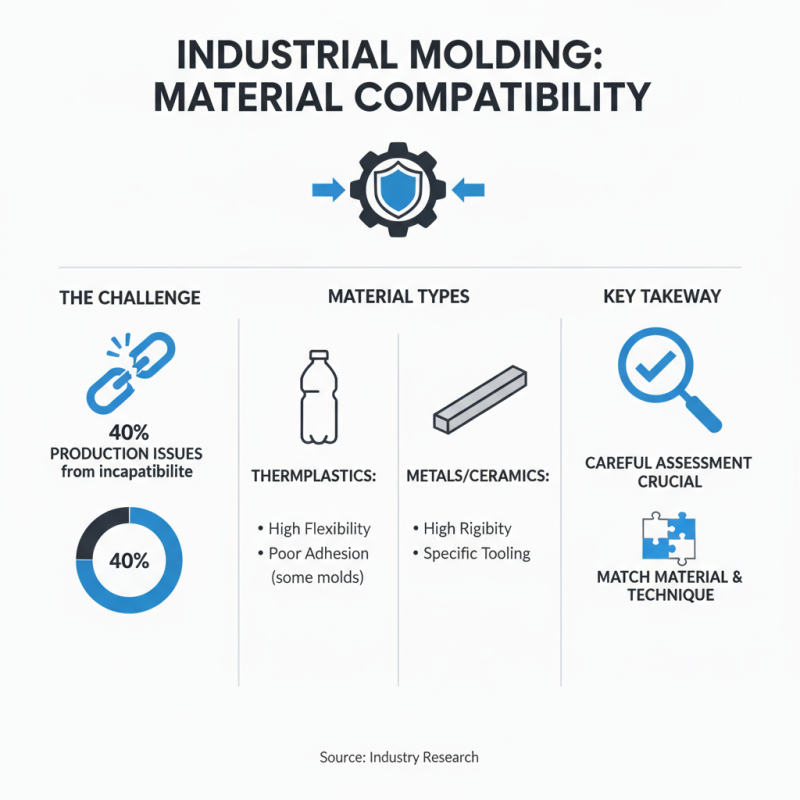

Material compatibility is crucial in selecting industrial molding techniques. Different materials present unique challenges and benefits. For instance, thermoplastics have high flexibility but may not adhere well to certain molds. Research indicates that nearly 40% of production issues stem from material incompatibility. This highlights the need for careful assessment during the selection process.

When evaluating materials, consider not only physical properties but also their chemical behavior. Some materials can react negatively when combined, leading to defects. For instance, PVC can release harmful substances when heated improperly. A study showed that 30% of manufacturers reported failures due to poor material selection. Therefore, choosing compatible materials can drastically improve production efficiency.

Cost implications are another factor when assessing material compatibility. A lesser-known fact is that materials that do not bond well can lead to higher waste rates. Industry data reveals that poor material choices can increase costs by up to 25%. While some materials may seem cheaper initially, their compatibility is the real game-changer in molding processes. Understanding these relationships is essential for long-term success in manufacturing.

Cost analysis is crucial in molding operations. Each technique has its own cost factors. Materials, labor, and machine maintenance all play a role. For instance, injection molding often requires expensive machinery. The upfront costs can be shocking. However, consider the long-term efficiency and volume potential. It may balance out over time.

Efficiency metrics are equally important. Monitoring cycle times can reveal production speed. A short cycle time usually means higher output. Yet, quality control must not be neglected. Poor quality can lead to costly rework. Companies often struggle to find this balance. They may cut costs too much, resulting in defective products.

Understanding these aspects can influence decision-making. Analyzing both cost and efficiency can guide you in selecting the right technique. Every option has trade-offs. Some may seem financially attractive but lack long-term viability. Awareness of these factors helps in making informed choices.