In the manufacturing sector, the selection of the right molding products is crucial for ensuring quality and efficiency. According to a report by Grand View Research, the global injection molding market is expected to reach $451.5 billion by 2027, reflecting a compound annual growth rate (CAGR) of 5.4%. This underscores the increasing reliance on molding products in various industries, including automotive, consumer goods, and electronics.

Choosing the appropriate molding products not only impacts production costs but also influences product quality and final output. As companies strive for competitive advantages, understanding the specifications and functionalities of various molding products becomes essential. This guide aims to illuminate the key factors to consider when selecting molding products tailored to your manufacturing needs, ensuring strategic decisions that support both operational excellence and product innovation.

When selecting molding materials for manufacturing, the first consideration should be the specific product requirements. Factors such as mechanical strength, thermal stability, and chemical resistance play a critical role in determining the most suitable material. For instance, if the final product will be exposed to high temperatures or harsh chemicals, it’s essential to choose a material that can withstand these conditions without degrading. Understanding the end-use application is vital to ensure longevity and performance.

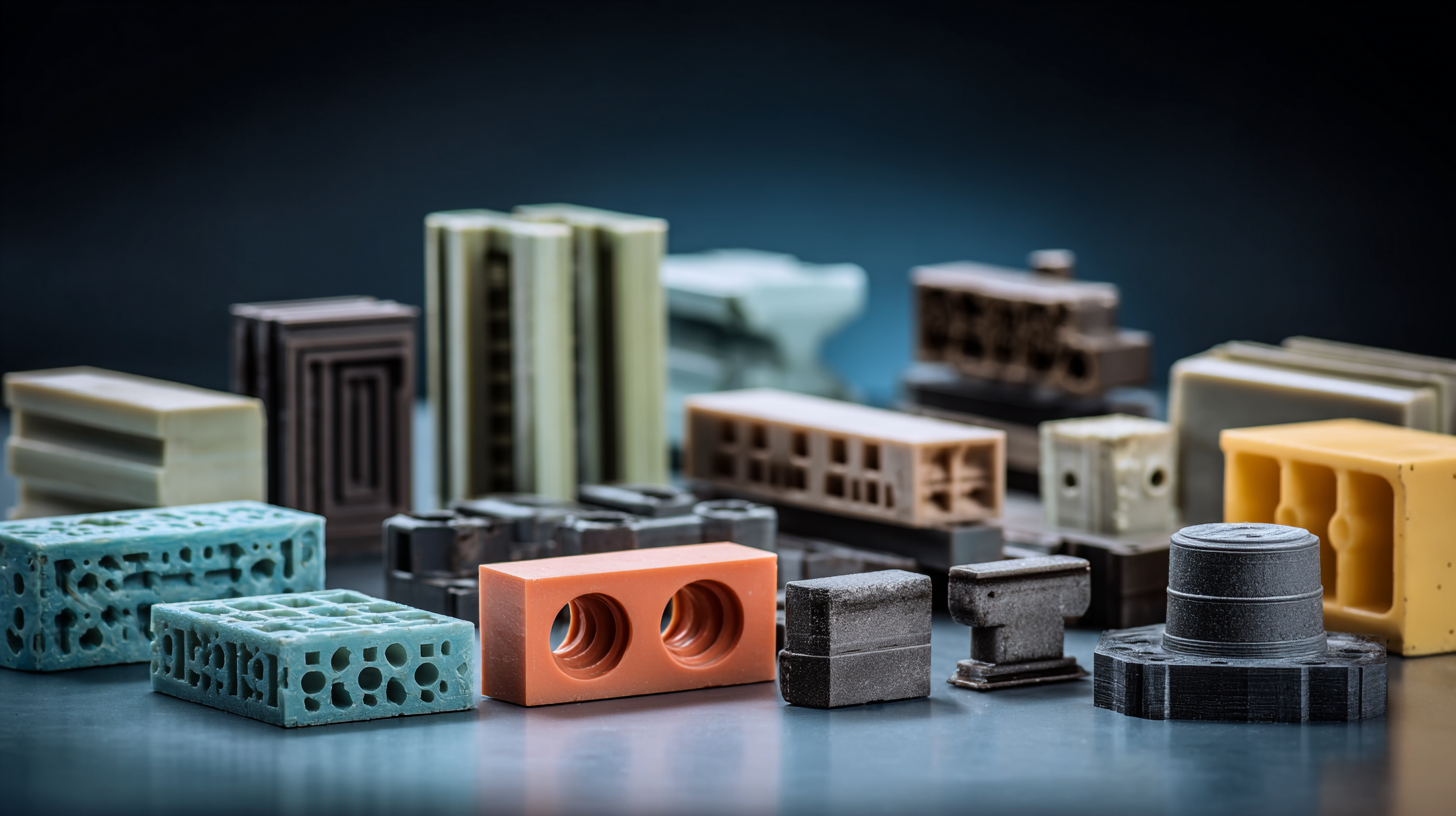

Another important aspect is the production process itself. The chosen molding material must be compatible with the desired manufacturing technique, whether it's injection molding, blow molding, or compression molding. Each process may require different material properties and processing techniques, so it’s crucial to align the material selection with the production method. Additionally, factors like cost-effectiveness and availability can influence the final decision, as sourcing materials that meet both performance criteria and budget constraints can be challenging yet necessary for successful manufacturing operations.

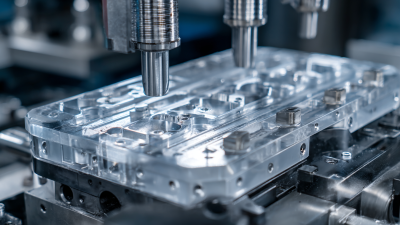

When selecting molding techniques for manufacturing, it's essential to evaluate the specific requirements of your project. Injection molding is renowned for its ability to produce high volumes of parts with precision and consistency. It is ideal for complex shapes and intricate designs, making it popular in industries such as automotive and consumer goods. However, the initial setup costs can be high, which makes it more suited for large production runs where the economies of scale can be realized.

On the other hand, blow molding is primarily used for creating hollow objects such as bottles and containers. This technique involves inflating a molten material into a mold, which can result in lightweight and durable products. When speed and material efficiency are crucial, blow molding offers a compelling advantage. Compression molding, another option, is often preferred for producing thicker parts and is well-suited for thermosetting plastics. It provides good surface finishes and is ideal for low-volume, high-quality applications. Understanding the strengths and limitations of each method is key to matching your manufacturing needs with the right molding product.

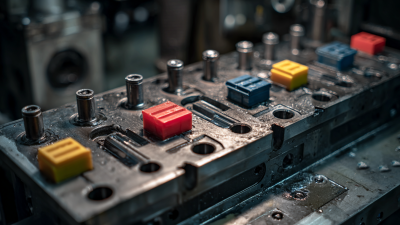

When selecting molding products, understanding tolerances and specifications is critical to ensuring the final product meets both functional and aesthetic standards. Tolerances define the permissible limits of variation in a physical dimension, which can significantly influence product performance.

For instance, according to a report from ASTM International, a mere 0.1 mm variance in molding allowances can lead to a 20% reduction in assembly compatibility, emphasizing the necessity for stringent control in manufacturing processes.

Specifications lay the groundwork for material choice, processing methods, and design parameters. Industry studies suggest that improper specifications can lead to a 30% increase in production costs due to rework and waste. For example, a survey by the Society of Plastics Engineers indicates that 75% of manufacturers report encountering challenges due to unclear specifications, highlighting a need for precise documentation during the design phase. Understanding how tolerances and specifications interact allows manufacturers to choose the right molding products effectively, thereby optimizing production efficiency and reducing costs.

When selecting molding products for manufacturing, it's crucial to analyze the cost-effectiveness of your options. Balancing quality and price can significantly impact your overall production efficiency and profitability. High-quality molding materials may come with a higher upfront cost, but they often result in fewer defects and lower maintenance costs over time. Therefore, it's important to evaluate the long-term benefits against the initial investment.

Tips: Consider conducting a lifecycle cost analysis. This approach allows you to compare the total costs associated with different molding products over their expected lifespan, rather than making decisions solely based on initial purchase price. Additionally, seek out suppliers who offer warranties or guarantees, which can provide added assurance of quality and value.

Furthermore, assess the specific needs of your manufacturing processes. Identify which attributes are non-negotiable for your applications—such as durability, temperature resistance, or precision. This will help you narrow down your options to products that deliver the best performance for your requirements while staying within budget. A thorough understanding of your manufacturing needs will enable you to choose molding products that provide the best balance of quality and affordability.

Sustainability has become a critical focus in the manufacturing sector, prompting businesses to rethink their material choices and processes. When selecting molding products, opting for eco-friendly materials is vital to minimizing environmental impact. Biodegradable plastics, for instance, play a significant role in the circular economy by providing alternatives that can decompose and reduce landfill waste. These materials thrive under proper conditions, breaking down into non-toxic components, thus alleviating some of the issues associated with conventional plastics.

Tips: Consider exploring sustainable fiber-reinforced composites, which leverage renewable and biodegradable fibrous materials. This not only enhances the ecological footprint but also offers innovative properties for various applications. Additionally, the development of sustainable 3D-printed packaging from agricultural waste showcases how creative solutions can reshape molding practices, fostering a greener future.

Another emerging trend is the use of sustainable mold biomachining for manufacturing microfluidic devices. This method offers an effective alternative to conventional techniques, ensuring that production processes are environmentally friendly. By embracing these sustainable practices, manufacturers can contribute to a more resilient and eco-conscious economy.