In today's competitive manufacturing landscape, choosing the right production method is crucial. Experts highlight the benefits of injection molding projects for various industries. John Smith, a seasoned expert in the field, once stated, "Injection molding is the backbone of efficient manufacturing."

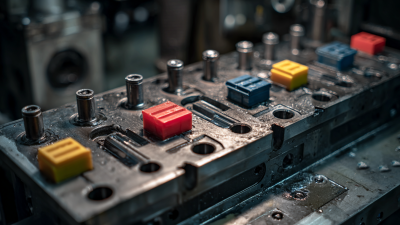

Injection molding projects offer precision and speed. They can produce complex shapes quickly, reducing time-to-market. This efficiency is vital for businesses aiming to stay ahead. However, companies must consider setup costs and design intricacies. A poorly designed mold can lead to waste and increased expenses. Reflecting on these challenges is essential for success.

Despite some downsides, the advantages often outweigh the drawbacks. Reliable production at scale is attainable through injection molding projects. As industries evolve, so do production techniques. Adopting the right strategy can redefine manufacturing outcomes.

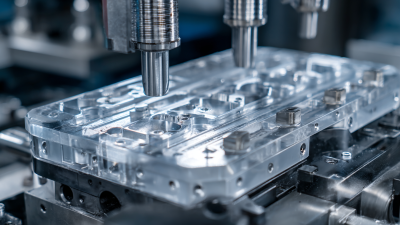

Injection molding has become a cornerstone of modern manufacturing. It offers numerous benefits that enhance production efficiency. Reports indicate that around 30% of all plastics manufactured globally utilize injection molding. This process allows for high-volume production with remarkable precision. Products can be designed with intricate details and complex geometries, which are often difficult to achieve with other methods.

In addition, injection molding reduces waste significantly. Traditional machining processes can generate up to 50% waste from raw materials. In contrast, injection molding minimizes waste to as low as 3%. This process proves more sustainable and cost-effective for businesses aiming to streamline their manufacturing processes while reducing their environmental footprint.

**Tips**: Consider investing in advanced molding technology. It can improve product quality and reduce cycle times. Also, prioritize regular maintenance of machines. A well-maintained machine performs better and ensures consistent output. Think about training staff on the latest industry practices. Skilled workers can elevate production efficiency and product quality. Reflection on process improvements is key to staying competitive in this evolving landscape.

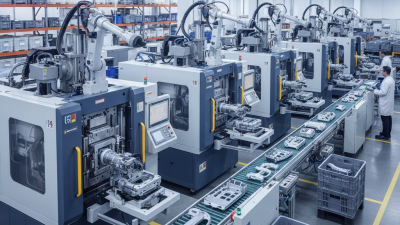

Injection molding is a pivotal technique across various industries. Its efficiency and versatility make it a popular choice for many manufacturers. The automotive sector, for instance, heavily relies on injection molding for producing complex parts. According to a report by Grand View Research, the automotive segment accounts for over 30% of the global injection molding market. This growth reflects the increasing demand for lightweight and durable components, which injection molding readily provides.

Healthcare is another critical industry utilizing injection molding. Medical devices require high precision and strict compliance with safety standards. A study from MarketsandMarkets shows that the medical injection molding market is expected to reach $5.2 billion by 2026, growing at a CAGR of 7.4%. This highlights the significant role of injection molding in creating sarcophagi for medical equipment, ensuring both reliability and safety.

However, the process is not without challenges. Quality control remains a concern, as defects can arise during production. Factors such as temperature variability and material inconsistencies can lead to flaws. These issues require ongoing assessment and quality checks to ensure optimal production. The evolving technology in injection molding can help mitigate some of these concerns, but it is imperative for manufacturers to stay vigilant and adaptable.

| Industry | Applications | Benefits |

|---|---|---|

| Automotive | Dashboard components, bumpers | High precision, durability |

| Consumer Electronics | Casing, connectors | Complex designs, high-volume production |

| Medical Device Manufacturing | Syringes, surgical instruments | Sterility, precision, compliance with regulations |

| Packaging | Bottles, containers | Cost-effectiveness, lightweight solutions |

| Toys and Games | Action figures, board game pieces | Wide variety of shapes and colors, safety standards |

Injection molding is renowned for its cost-effectiveness. This method produces high-quality parts quickly, making it ideal for large production runs. The cost per unit decreases as the volume increases, making it more economical over time. In contrast, other manufacturing methods may incur higher labor costs or longer lead times.

Consider a situation where a company needs precise parts. Injection molding allows for tight tolerances. This precision reduces material waste, which adds to cost savings. However, initial setup costs can be steep. Companies must weigh these expenses against potential savings in mass production.

While injection molding offers many benefits, there are challenges to consider. The molds can be expensive and time-consuming to create. If a design change occurs, it may lead to additional costs. Companies must reflect on these factors. In some cases, alternative manufacturing methods might be more suitable for lower volume needs. Each project is unique and requires careful evaluation.

Injection molding is a popular choice for manufacturers seeking scalability and efficiency. This technique transforms raw plastic into precise parts quickly. According to industry reports, injection molding can reduce production time by up to 50% compared to traditional methods. This speed translates to faster product launches and better market responsiveness.

The scalability of injection molding also stands out. Manufacturers can easily adjust production volumes based on demand. A study shows that companies leveraging this technology can achieve over 25% cost savings in larger production runs. However, it’s essential to plan for initial setup costs, which can be high. Some may find these upfront expenses challenging to manage.

Tips: Evaluate your project’s needs before committing. Not all designs suit injection molding. Consider cycle times carefully. Coordinating design adjustments early can lead to cost-effective changes later on. Balancing efficiency and adaptability can be tricky, but it’s crucial for sustainable growth.

Injection molding offers significant design flexibility and a wide range of material options, making it a preferred choice for many manufacturing projects. This method allows for intricate designs that would be challenging or impossible with other manufacturing techniques. Complex shapes can be achieved with ease, and parts can include various features like undercuts, textures, and precise dimensions. However, achieving the perfect design often requires multiple iterations and adjustments.

Another advantage of injection molding is the variety of materials available. Manufacturers can choose from plastics, elastomers, and even some metals. Each material comes with unique properties suited for different applications. For instance, durable plastics are great for consumer goods, while special compounds work well in automotive parts. Yet, it's essential to consider that not all materials perform equally in every application.

Even with its many benefits, challenges do arise. Not all designs can be easily translated into a mold, leading to potential redesigns. Additionally, the initial cost of creating molds can be high. This means evaluating the project’s scale and long-term needs is crucial. Reflecting on these factors can help manufacturers make informed choices about their injection molding projects.