Choosing the best low pressure molding machine can be challenging. This decision impacts your production efficiency and product quality. Numerous factors need careful consideration before making a selection.

When narrowing down options, consider your specific needs. What materials will you use? Are you focusing on intricate designs or mass production? The answers guide you toward the right machine. It’s essential to evaluate the machine's adaptability and precision. A good low pressure molding machine should meet your production demands reliably.

Don’t overlook the importance of supplier support. Assess their reputation and service offerings. Sometimes, the best machine might not be the one with the most features. A machine should align with your operational goals. Reflecting on these aspects can ensure long-term success in your manufacturing processes.

Low pressure molding technology has carved a niche in various industries, including electronics, automotive, and medical devices. It offers a unique blend of durability and flexibility in manufacturing processes. This method utilizes thermoplastic materials that flow easily under low pressure, allowing for intricate designs. The result is well-formed parts with less stress on delicate components.

A major advantage of low pressure molding is its ability to encapsulate and protect sensitive electronic parts. This technology can create robust protective barriers without compromising the integrity of the components inside. However, choosing the right machine requires careful consideration. Factors like the size of the parts, material compatibility, and production volume are crucial. Rushing the decision may lead to inefficiencies or subpar results.

Many manufacturers overlook the importance of thorough testing with different materials. This step can provide insights into the most effective solutions. Additionally, investing in a machine that offers versatility may seem appealing, but may not always align with specific needs. Balancing flexibility with targeted applications can often pose a challenge. Understanding the nuances of low pressure molding is essential for optimal product development.

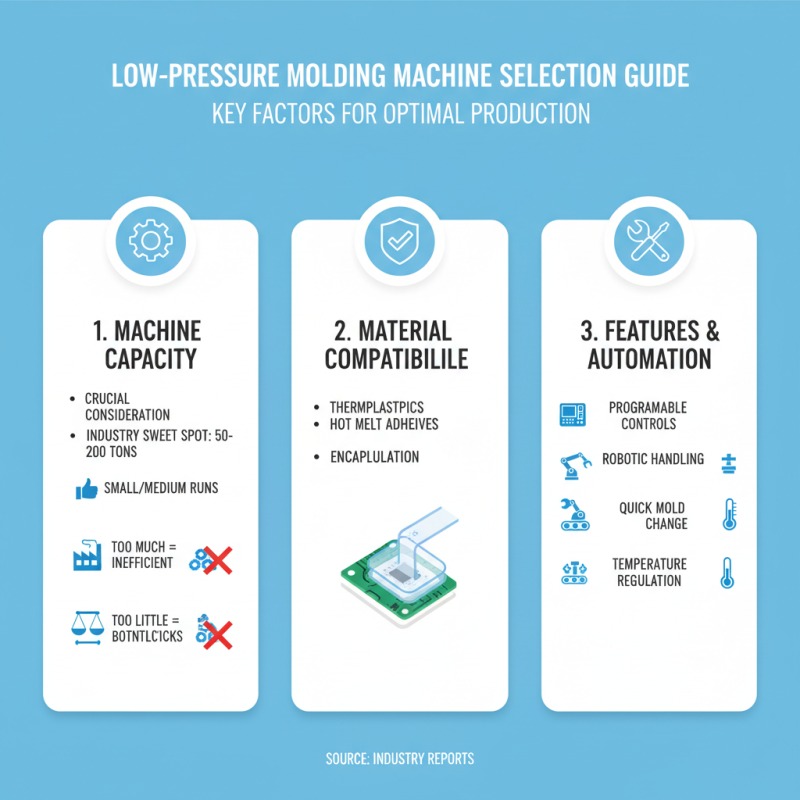

When selecting a low pressure molding machine, there are several key factors to consider. The machine’s capacity is crucial. Data from industry reports suggest that machines with a capacity of 50-200 tons are popular for small to medium production runs. Too much capacity can lead to inefficiencies. Conversely, too little can result in bottlenecks.

Material compatibility is another vital aspect. Different machines work better with specific thermoplastics and elastomers. Research shows that nearly 30% of production issues stem from material mismatch. It's essential to ensure the chosen machine aligns with your materials to minimize defects.

Tips: Always consult with users regarding their experiences. Hands-on testing, if possible, can highlight both strengths and weaknesses. Check for available support and resources. Investigating warranty options is also wise. Note that poorly maintained machines lead to unexpected downtime, affecting production schedules. Consider the long-term costs associated with maintenance and repairs, which often weigh heavily on overall expenses.

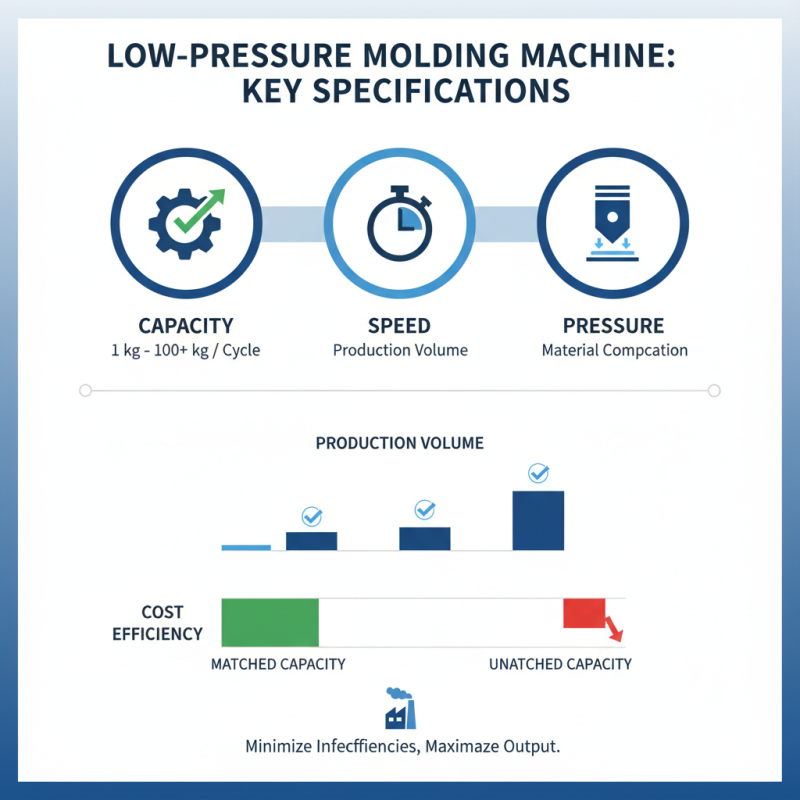

When choosing a low pressure molding machine, evaluating key specifications is essential. Capacity, speed, and pressure are critical factors. For instance, a machine’s capacity often determines production volume. According to industry reports, machines typically range from 1 kg to over 100 kg of material processed per cycle. A mismatch in capacity can lead to inefficiencies and increased operational costs.

Speed is another vital parameter. Many machines can operate at varying cycle times, generally between 30 to 120 seconds. Selecting a faster machine may seem appealing, but it can compromise the quality of the finished product. A report from an industry analysis firm highlights that a 20% increase in speed may reduce part accuracy by 15%. Therefore, it is crucial to balance speed with precision for optimal output.

Pressure is equally important. Most low pressure machines operate between 30 to 150 psi. Each application may require different pressure settings. Using incorrect pressure can lead to underfilled molds or over-compression. Both scenarios create defective components, which incur additional waste and costs. Understanding these specifications is vital to ensure you select a machine that aligns with your production needs.

When selecting a low pressure molding machine, reliability is crucial. A machine's performance can greatly impact production efficiency. It's important to scrutinize the machine's components. Look at materials used in construction. Quality materials often indicate longer lifespan. However, some manufacturers may cut corners. This can lead to frequent maintenance issues later.

Maintenance requirements should also be assessed. Regular upkeep is essential for consistent performance. A reliable machine should have user-friendly maintenance features. Check if parts are easily accessible for servicing. Some machines require specialized tools for simple tasks. This can waste time and cause frustration.

Consider the manufacturer's support and resources. Comprehensive manuals should be available. Online tutorials can be invaluable. However, support is often lacking. Many users report difficulties in getting timely help. Ultimately, the goal is to choose a machine that offers both reliability and manageable maintenance. Making an informed decision saves time and money in the long run.

| Molding Machine Model | Reliability Rating | Maintenance Frequency | Ease of Maintenance | Cost of Maintenance |

|---|---|---|---|---|

| Model A | 4.5/5 | Monthly | Moderate | $$ |

| Model B | 4.0/5 | Bi-Weekly | Easy | $ |

| Model C | 3.8/5 | Quarterly | Difficult | $$$ |

| Model D | 4.2/5 | Monthly | Moderate | $$ |

When selecting a low pressure molding machine, cost and value are critical factors. A recent industry report indicates that initial acquisition costs can vary from $50,000 to $150,000. This wide range often depends on machinery capabilities and features. While lower-cost options may seem attractive, they may not offer advanced technology. This could lead to higher operational costs over time due to inefficiencies.

Moreover, the value derived from a machine is just as important as its price. According to an analysis, manufacturers that invest in high-quality systems report up to 30% less downtime. They also experience better material consistency, which improves overall product quality. Evaluating the total cost of ownership is necessary. Examine factors such as maintenance costs, energy consumption, and production speed. Sometimes, spending more upfront can yield significant savings in the long term.

It's crucial to assess your production needs against machine capabilities. Choosing an unsuitable machine can result in inefficiencies. Common mistakes include overestimating production volumes or underestimating material complexities. Take the time to analyze these aspects carefully. The right choice should align with your business goals and production demands. A miscalculation can lead to regrettable consequences in the future.